ADVANTAGES

-

Clog-free

Clog-free -

Reduce disposal cost

Reduce disposal cost -

Improves work environment

Improves work environment -

Power-saving

Power-saving -

Low noise and low vibration

Low noise and low vibration -

Easy operation and easy maintenance

Easy operation and easy maintenance -

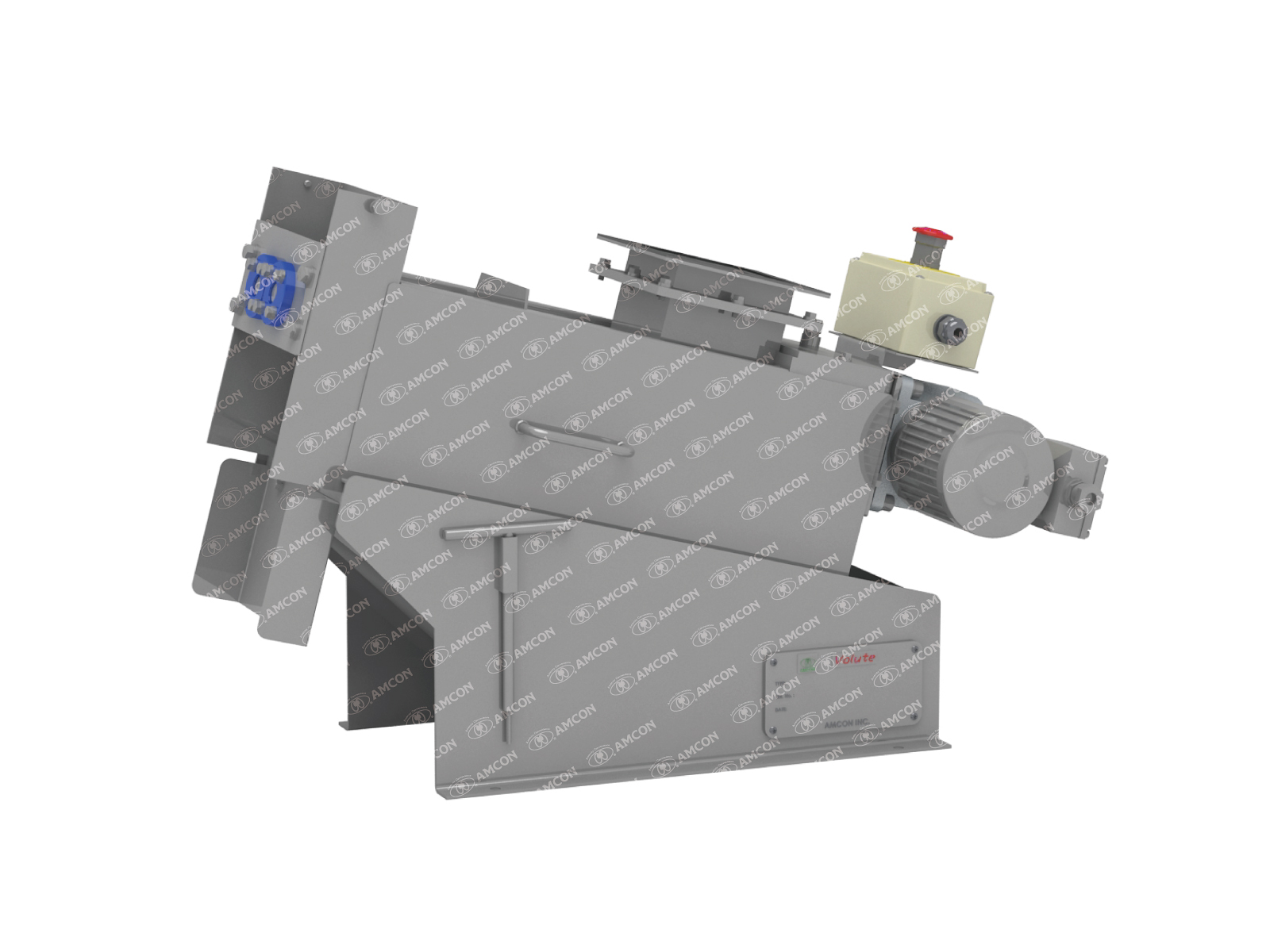

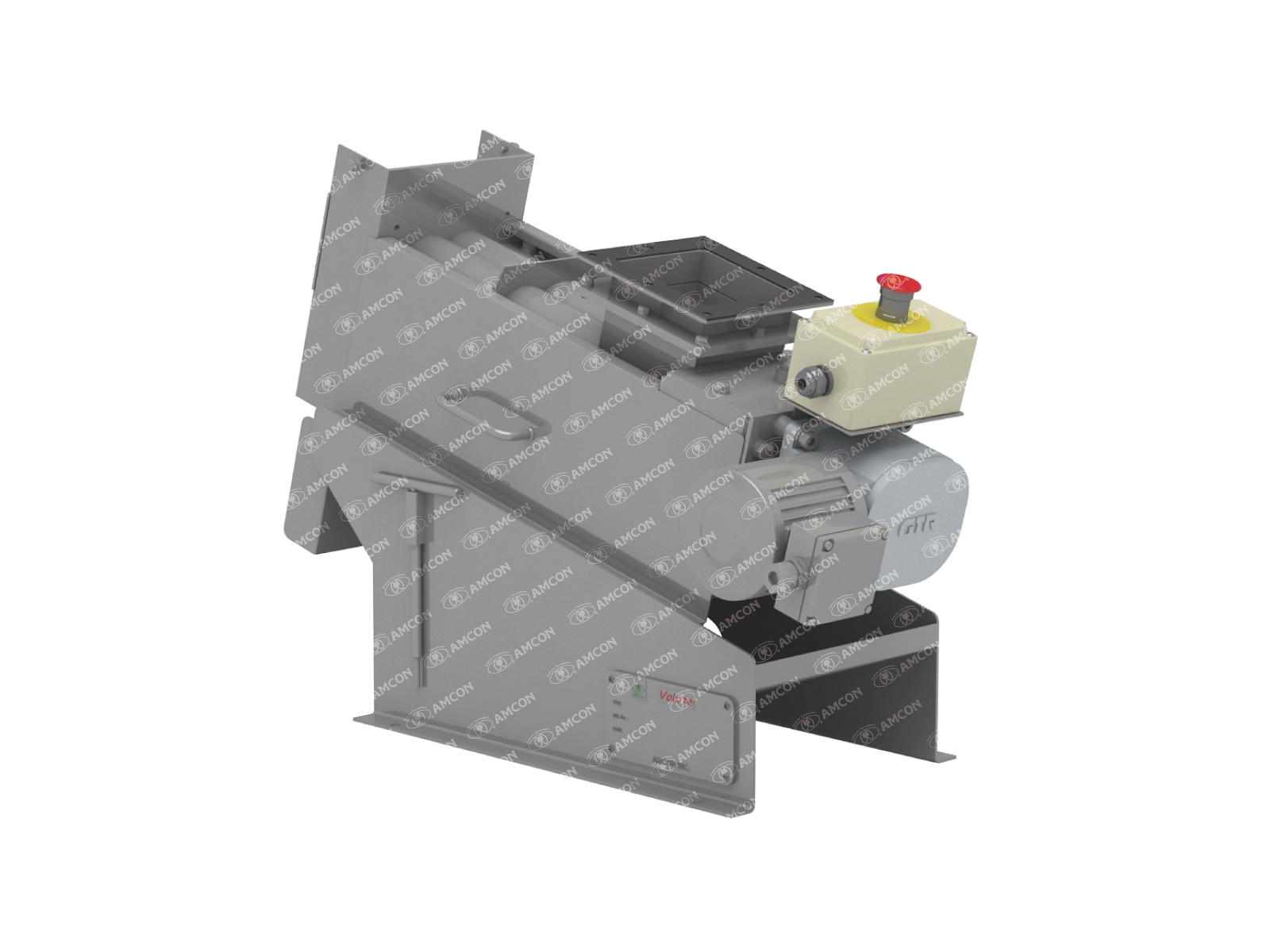

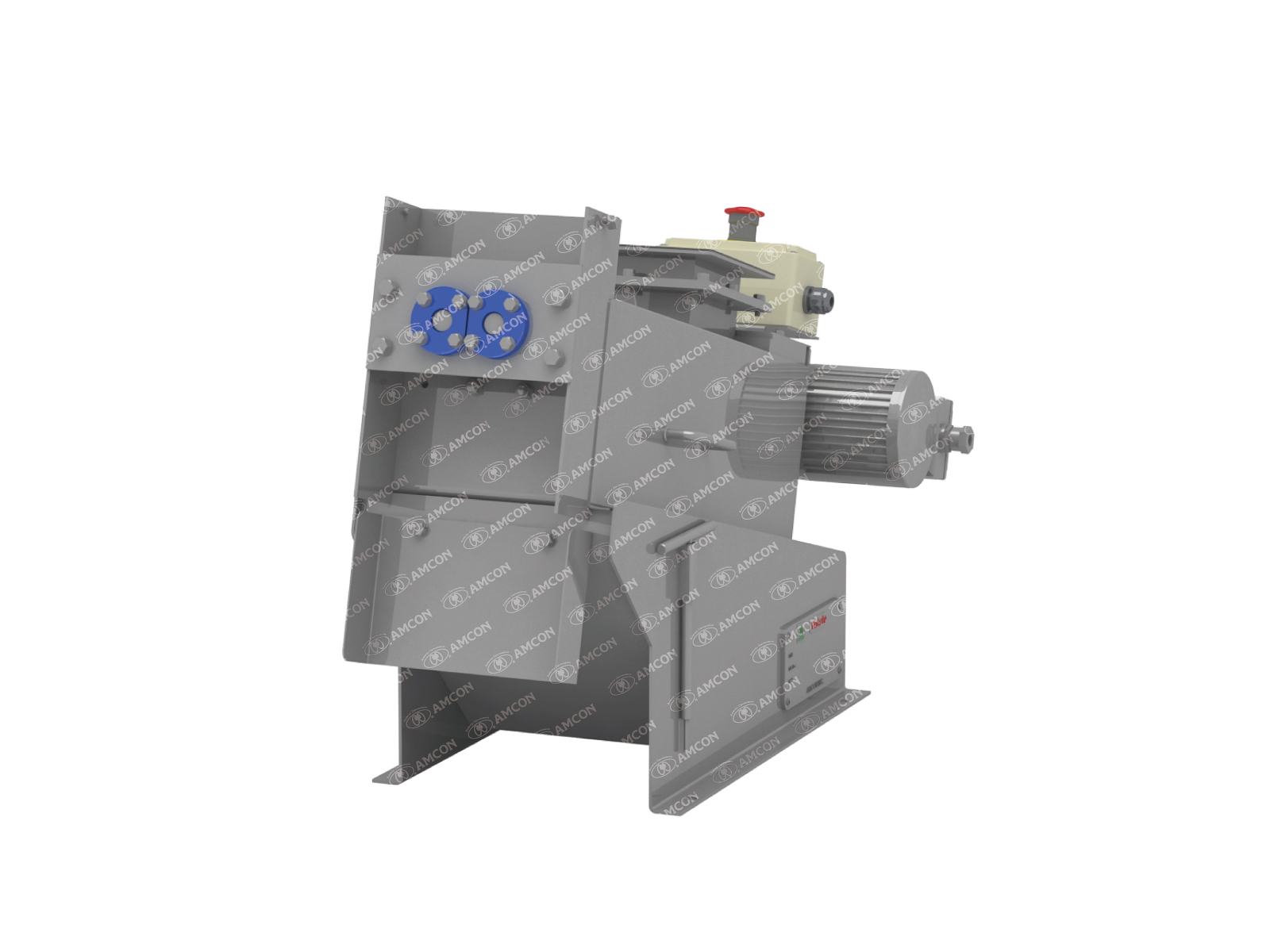

Small footprint

Small footprint

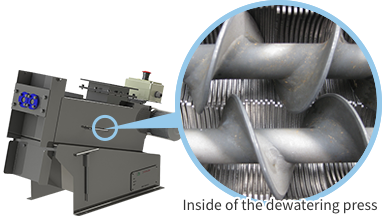

Clog-free

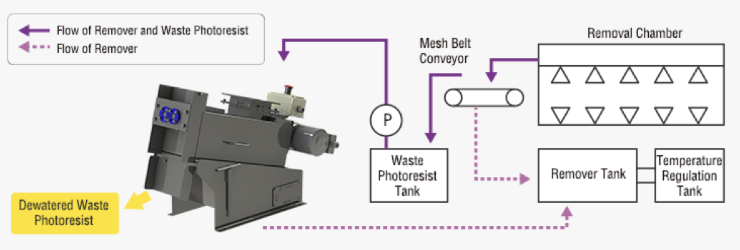

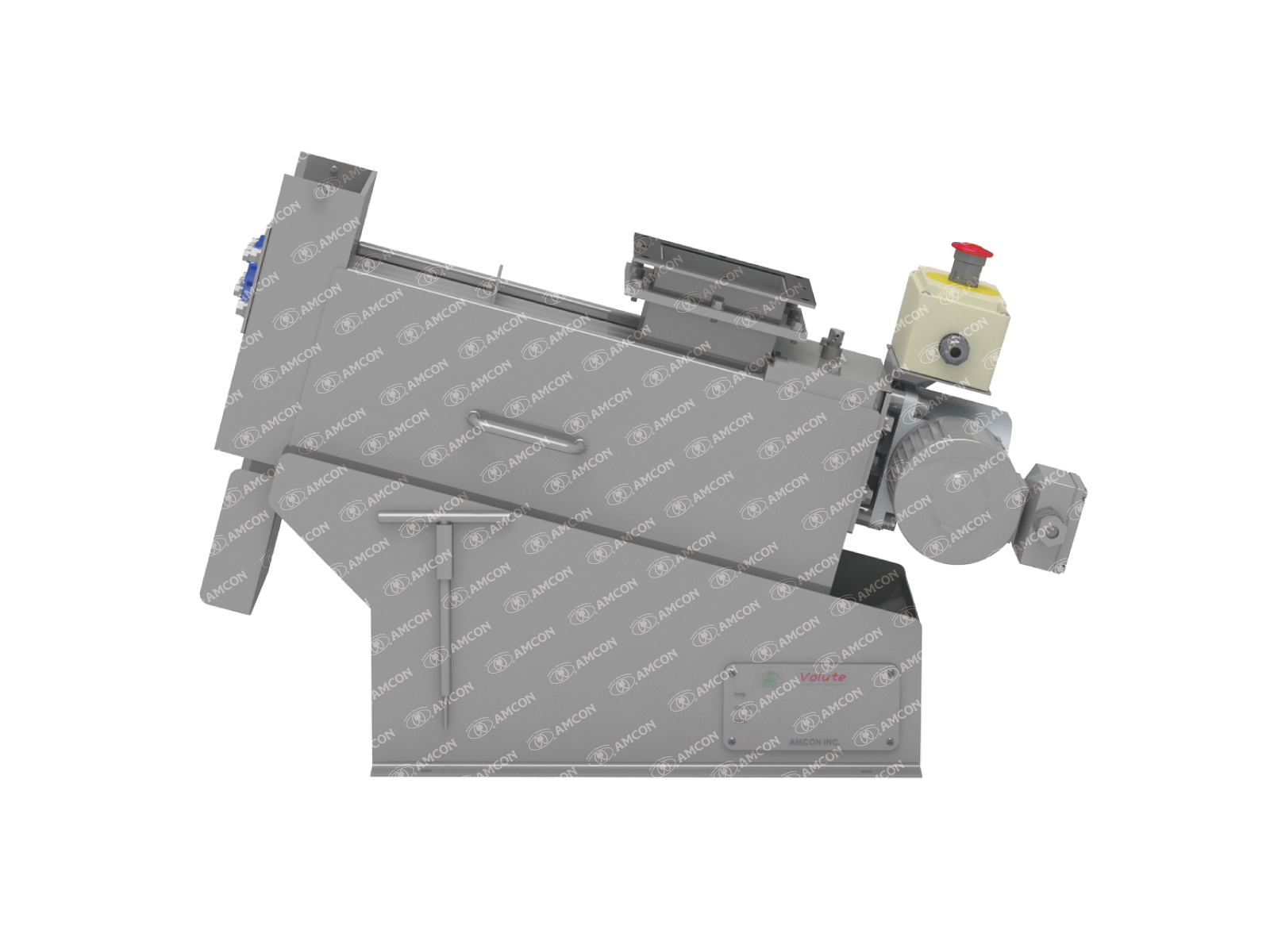

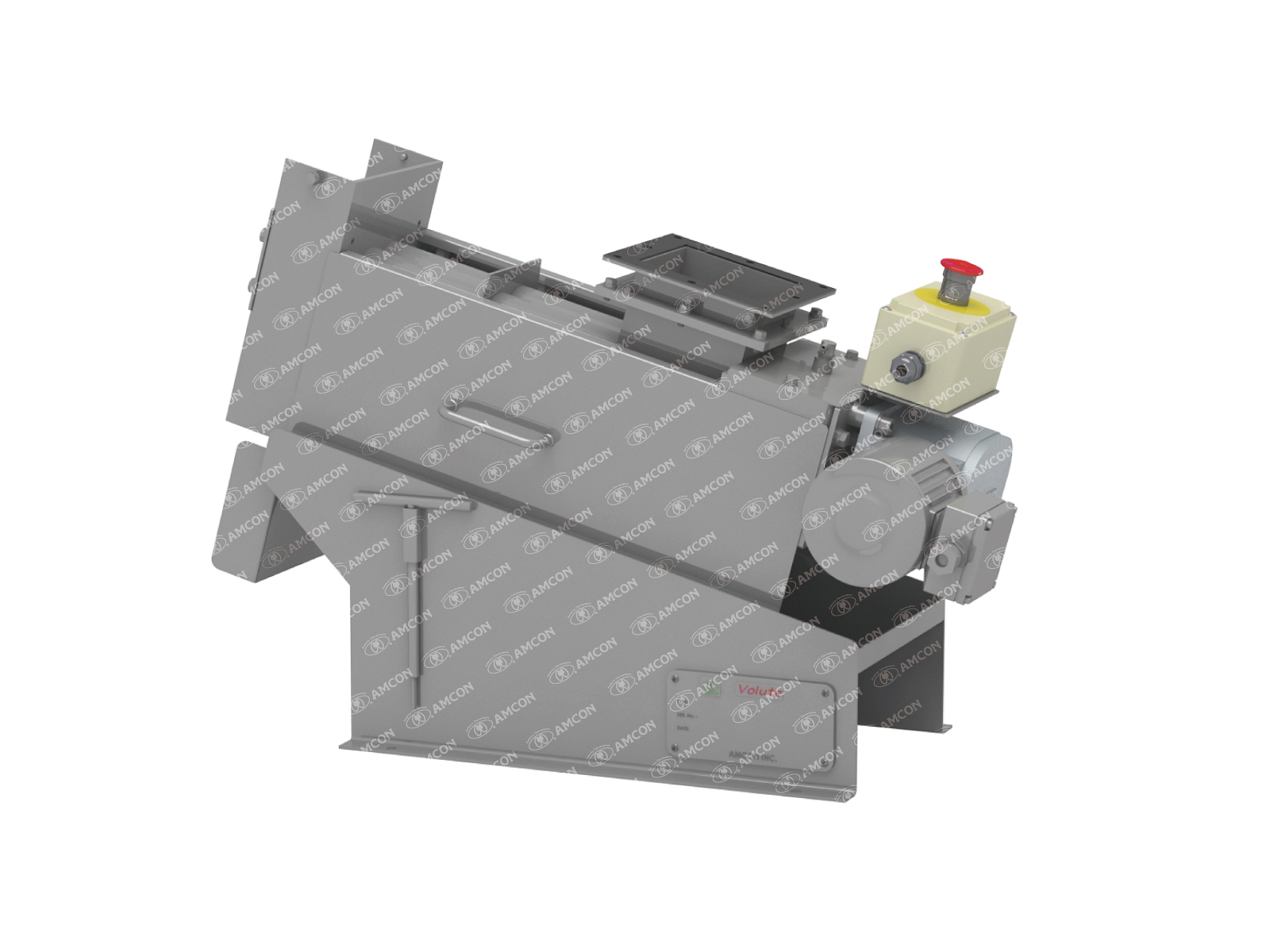

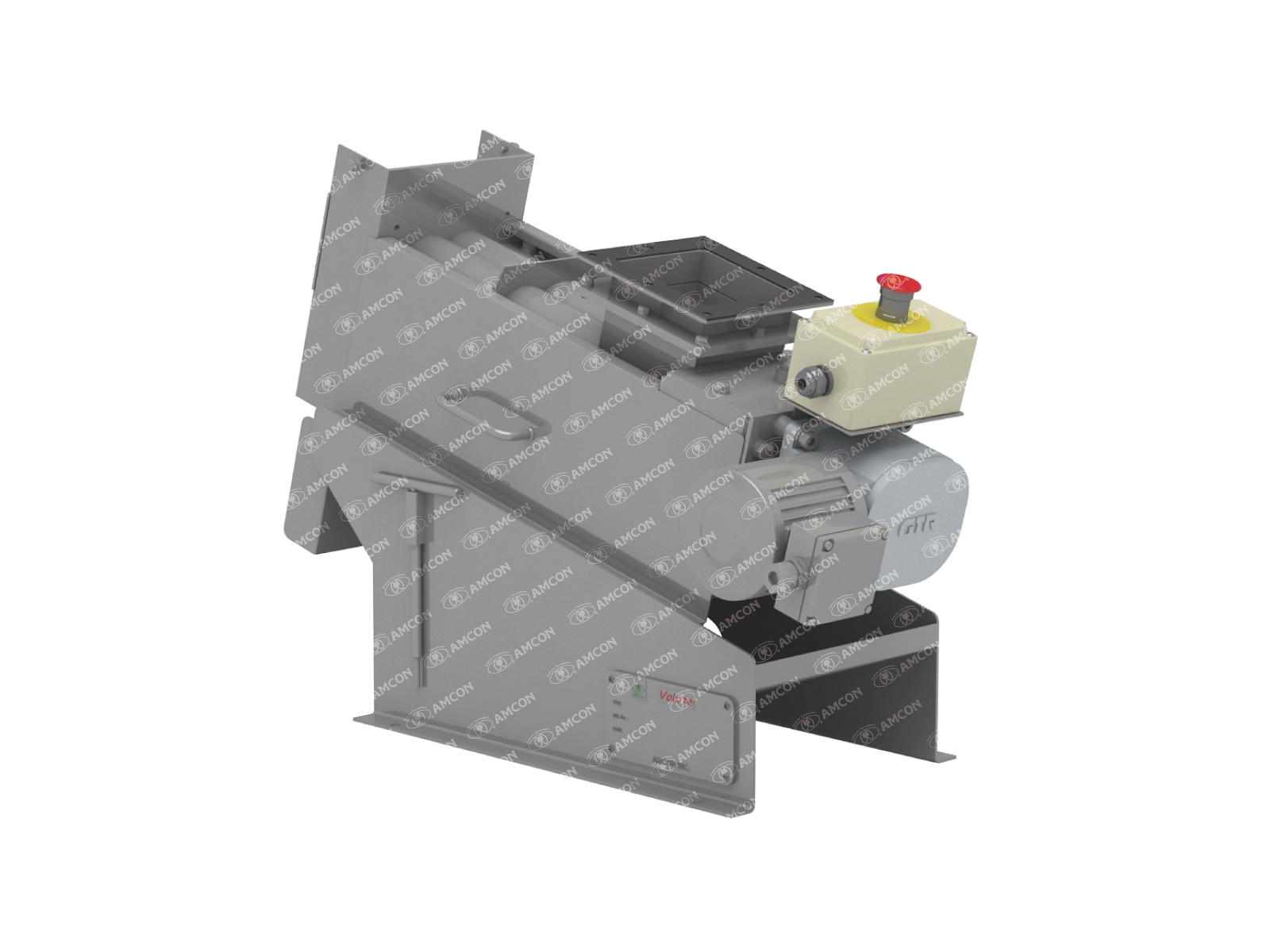

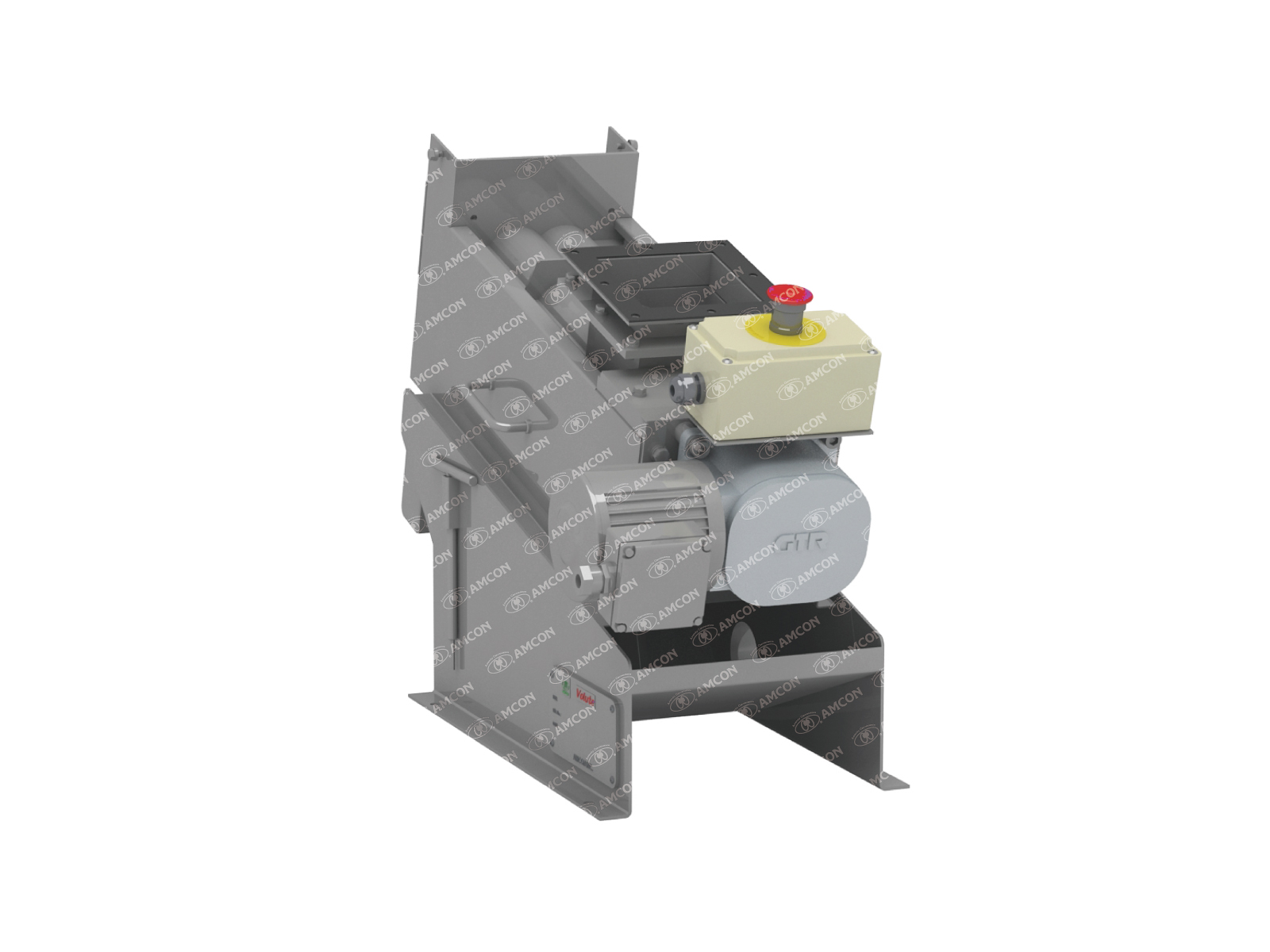

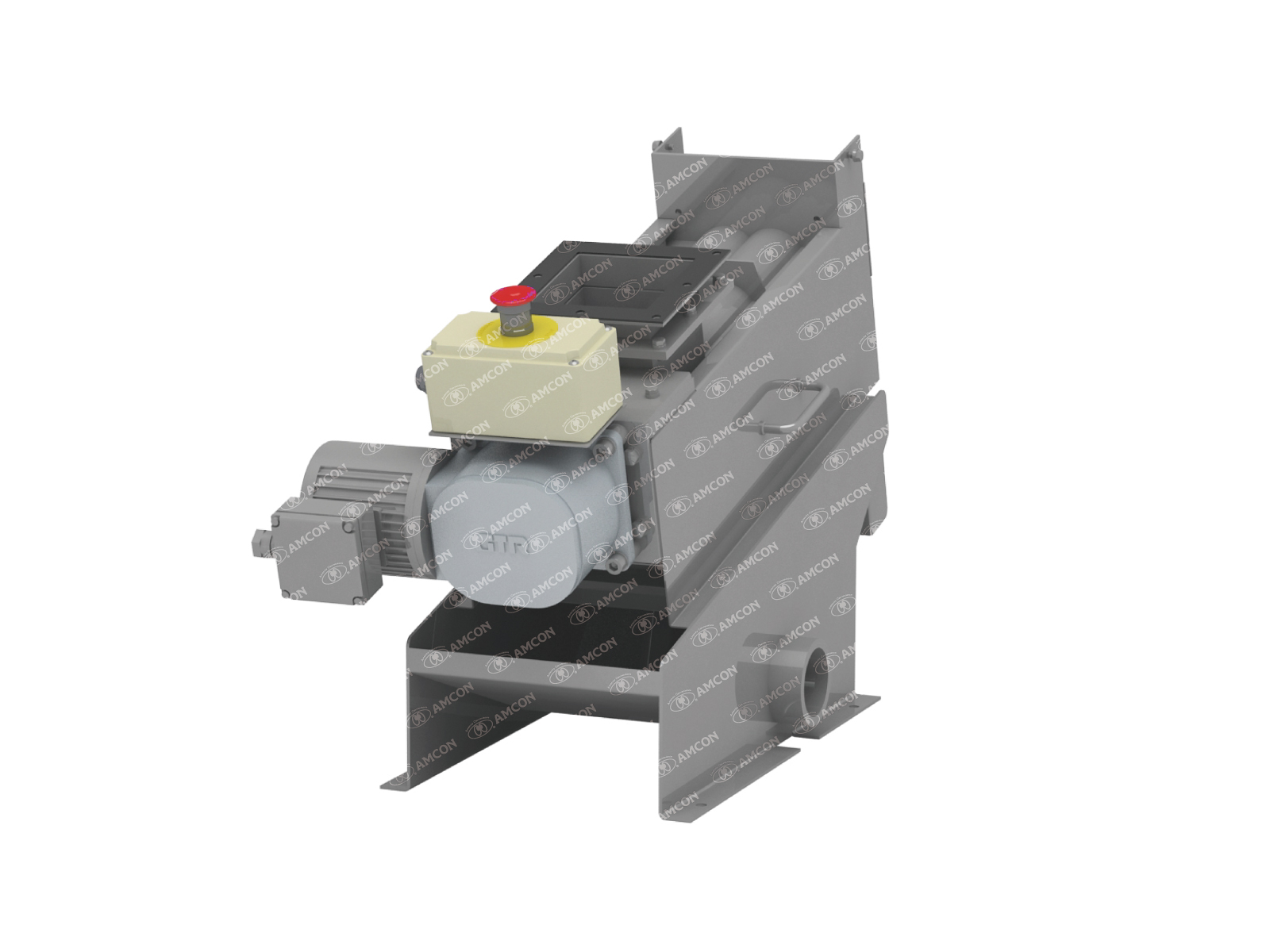

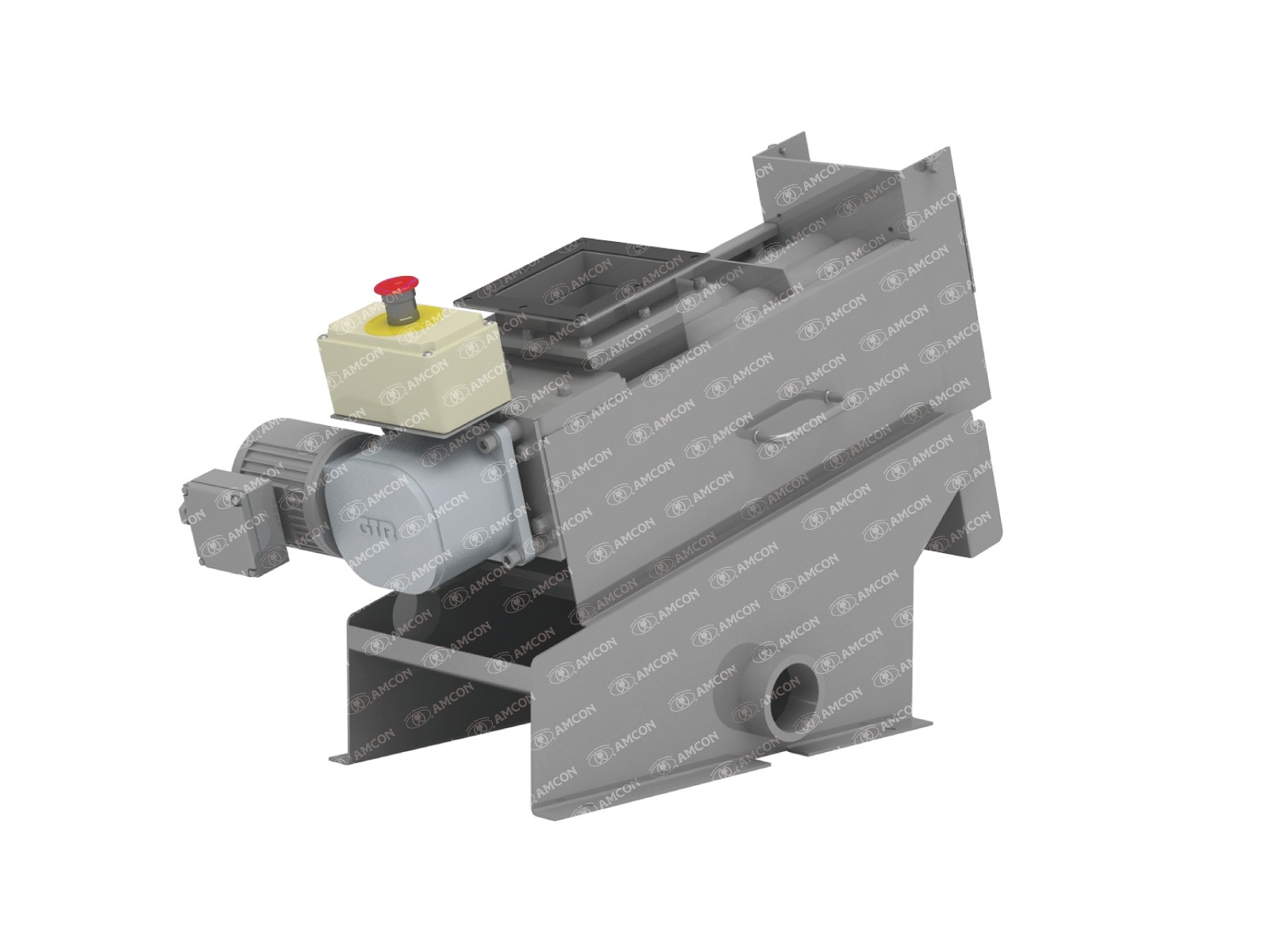

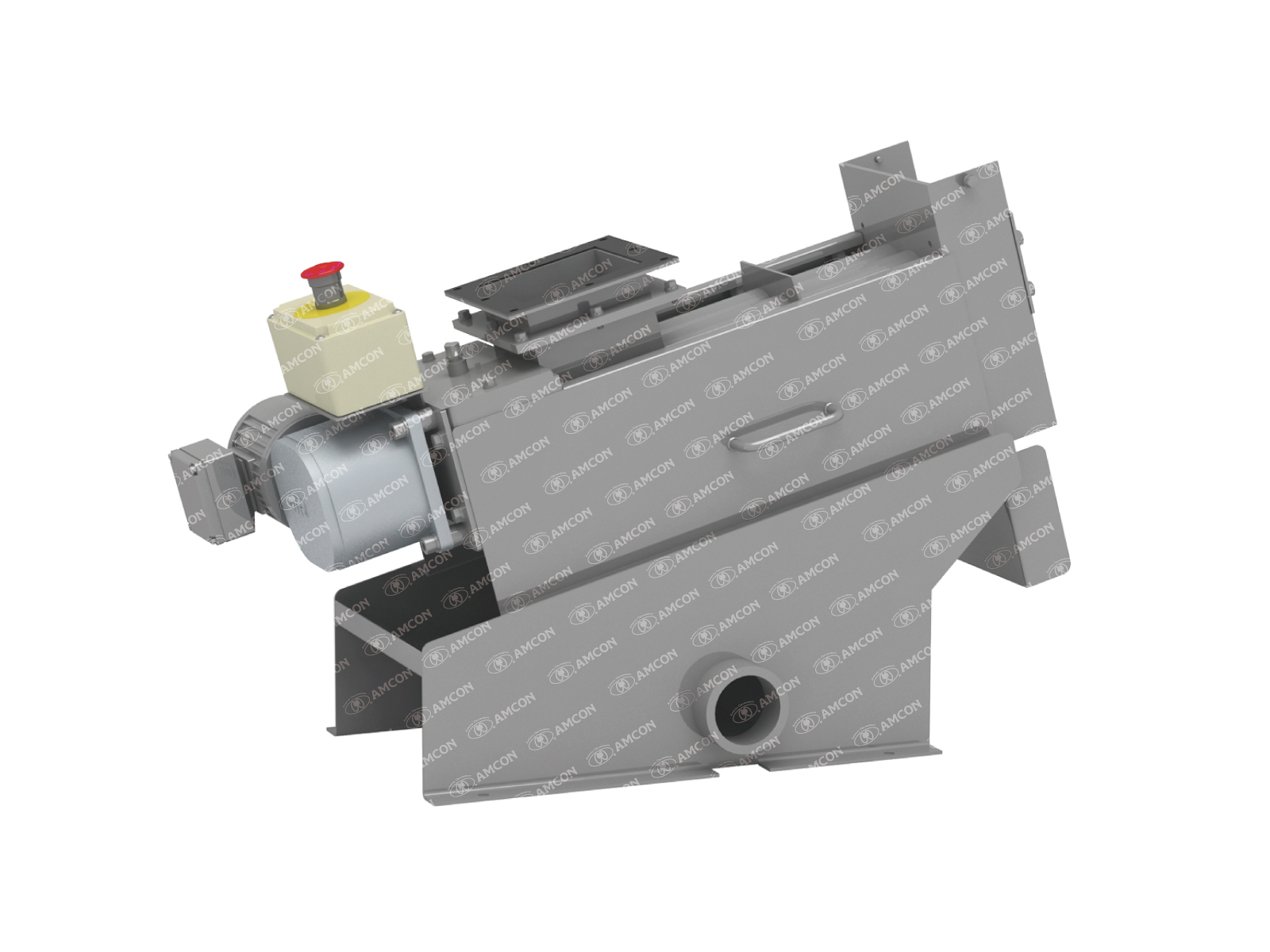

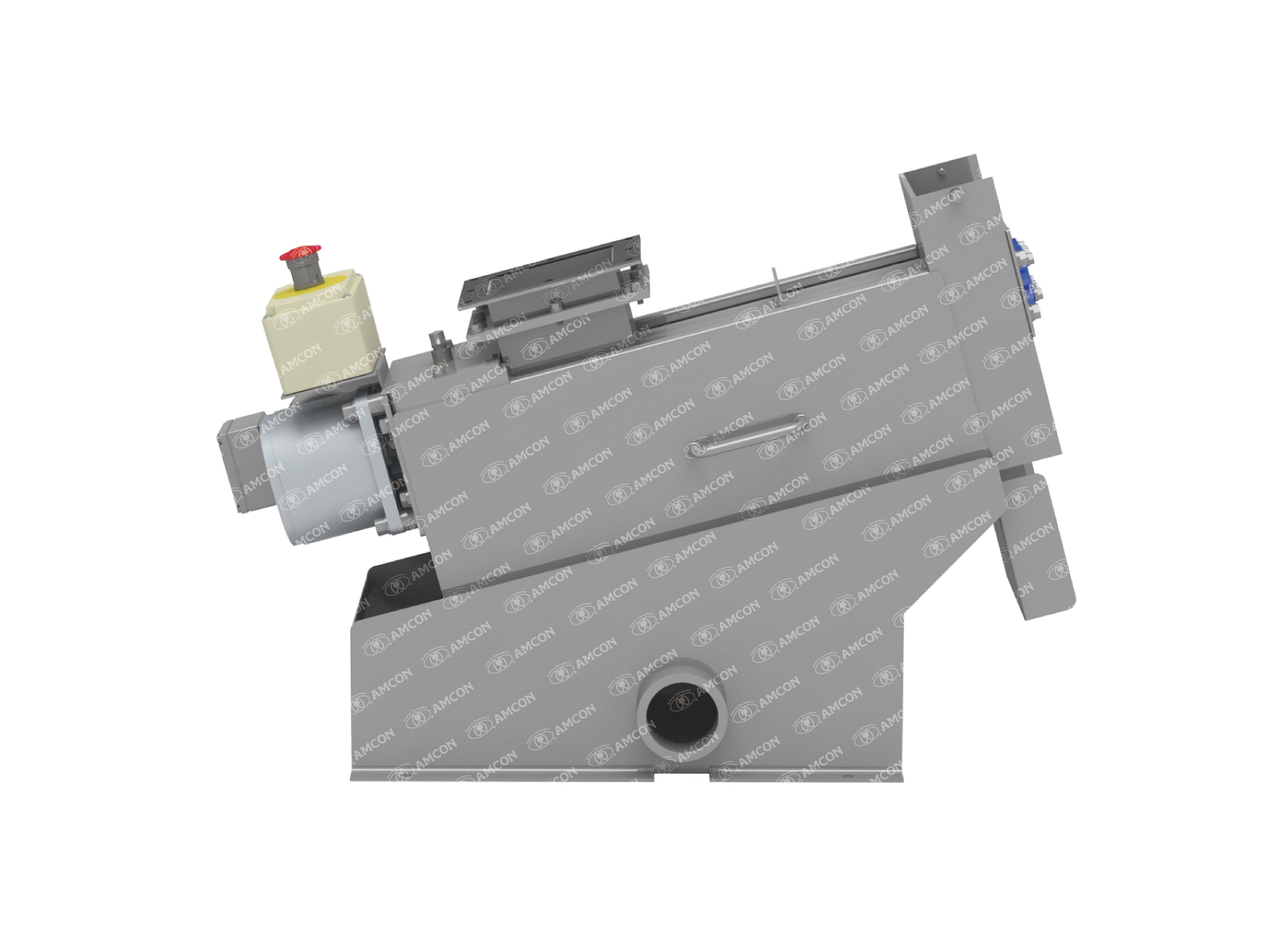

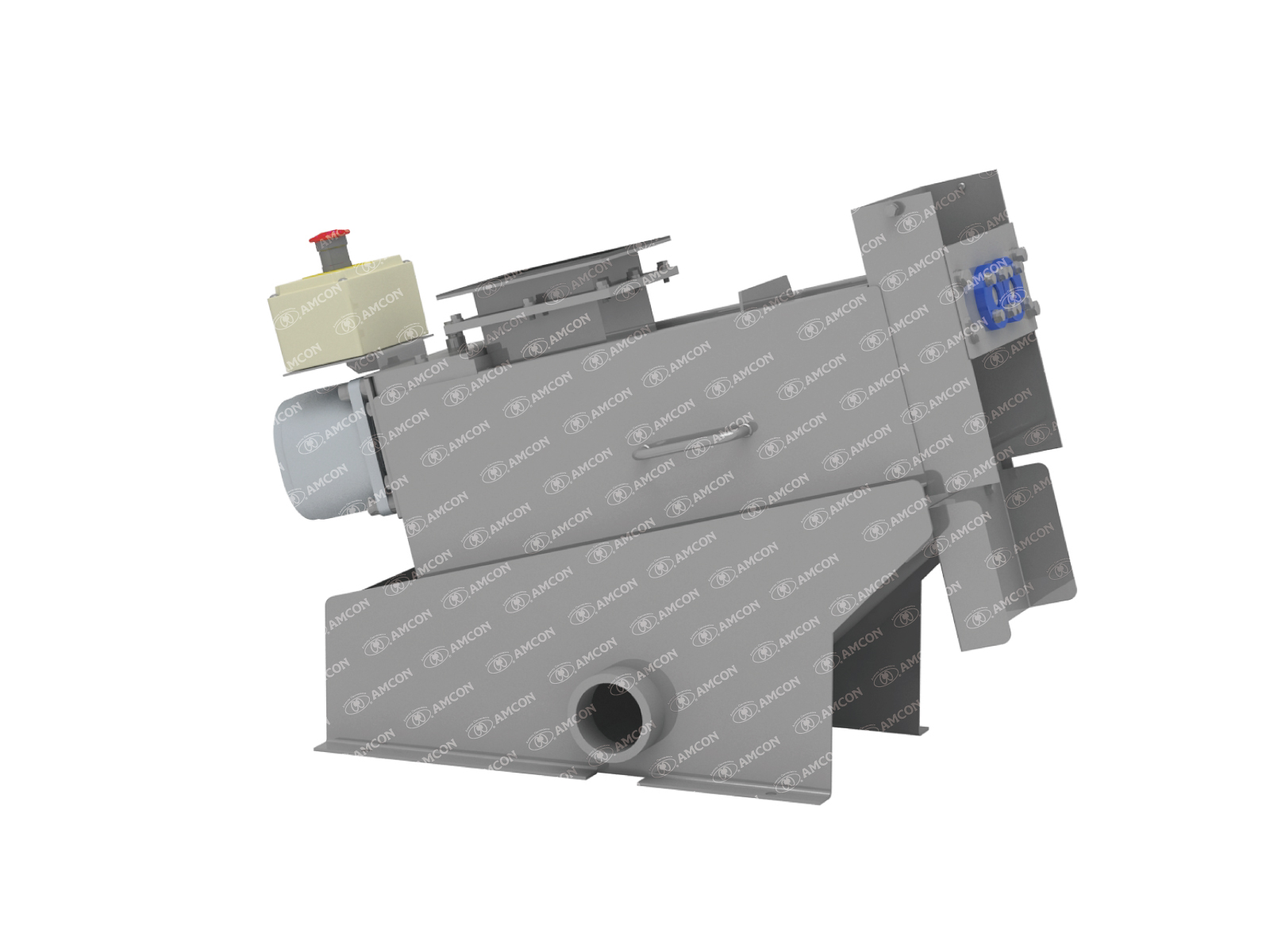

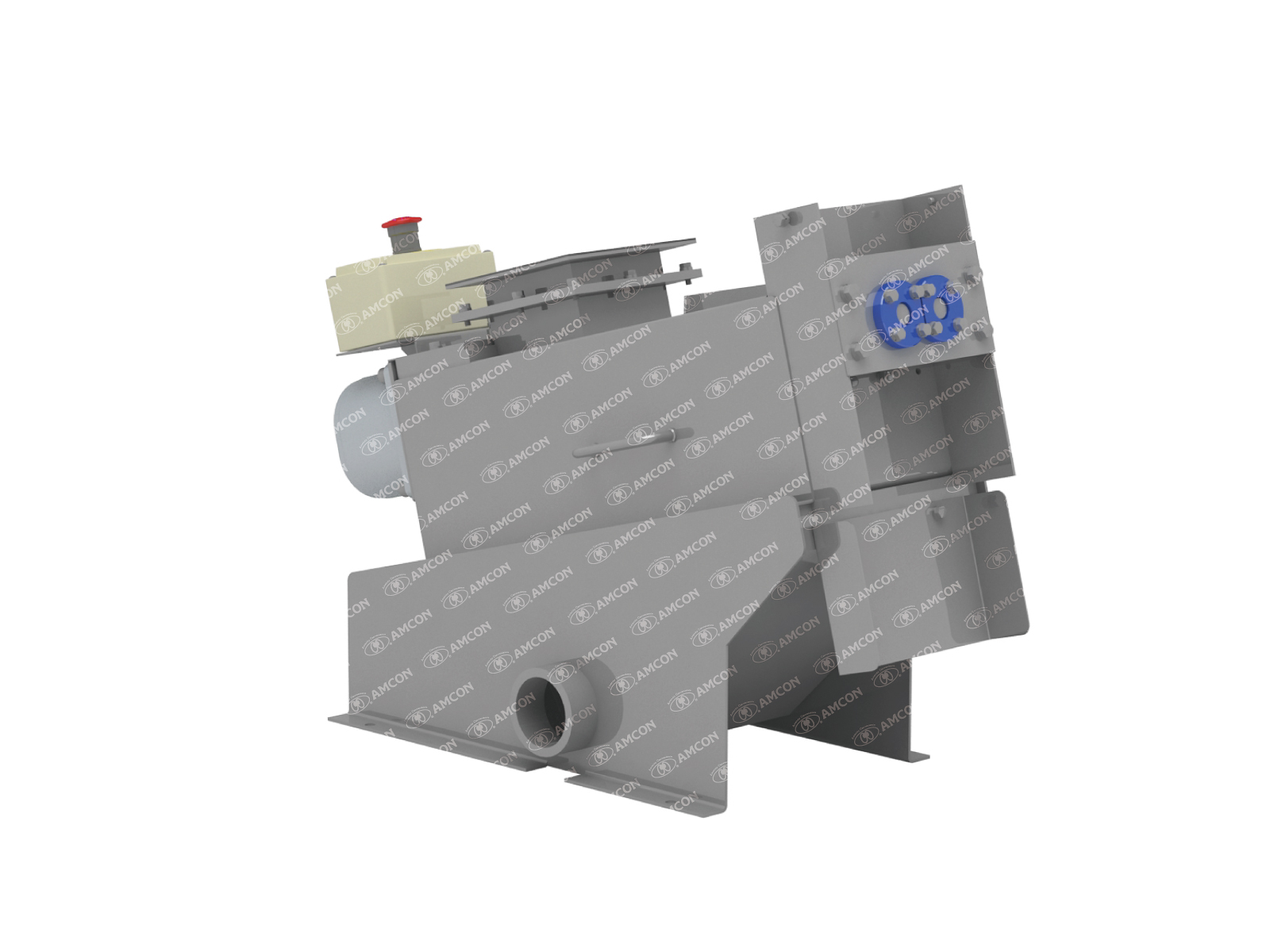

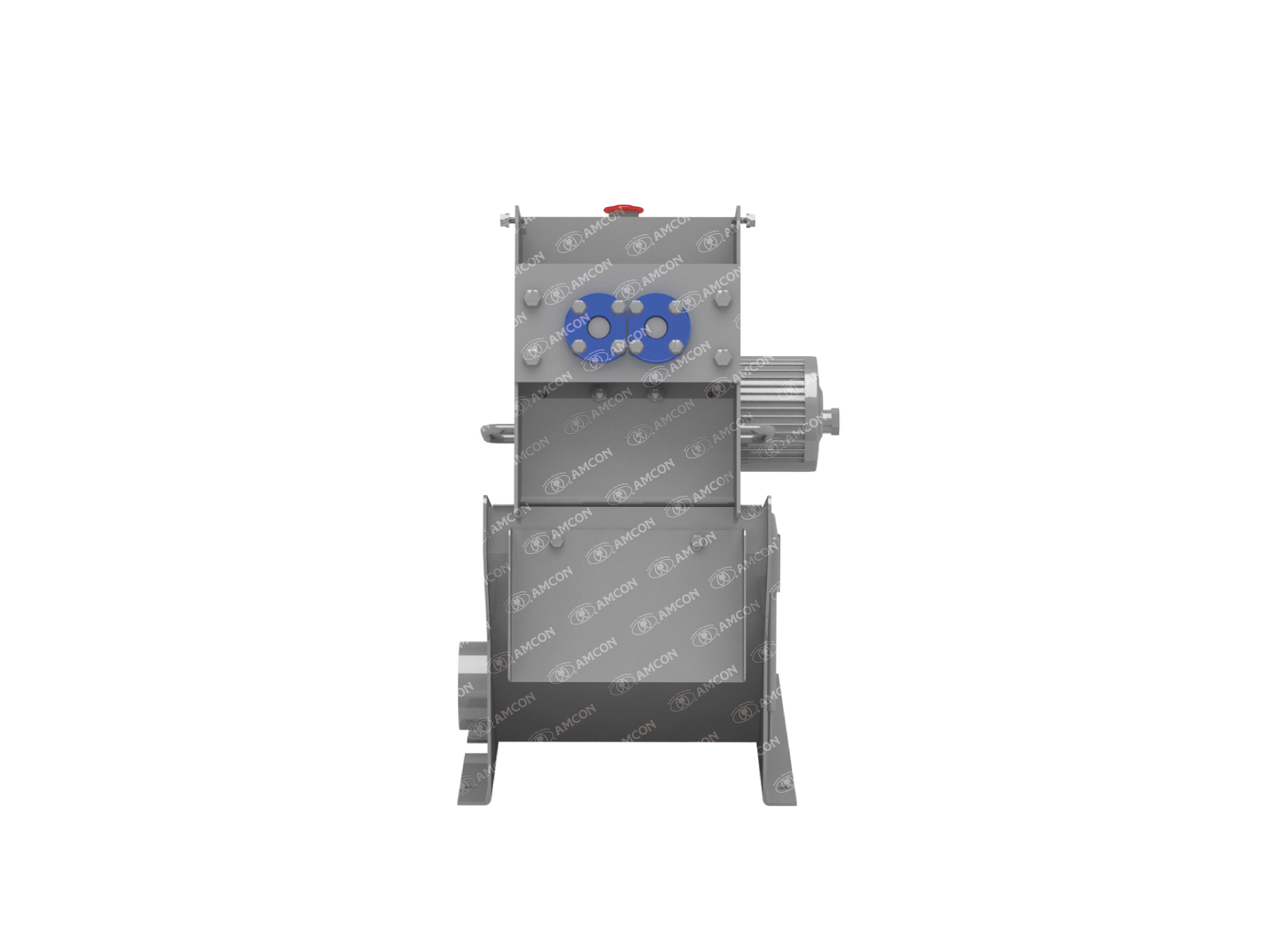

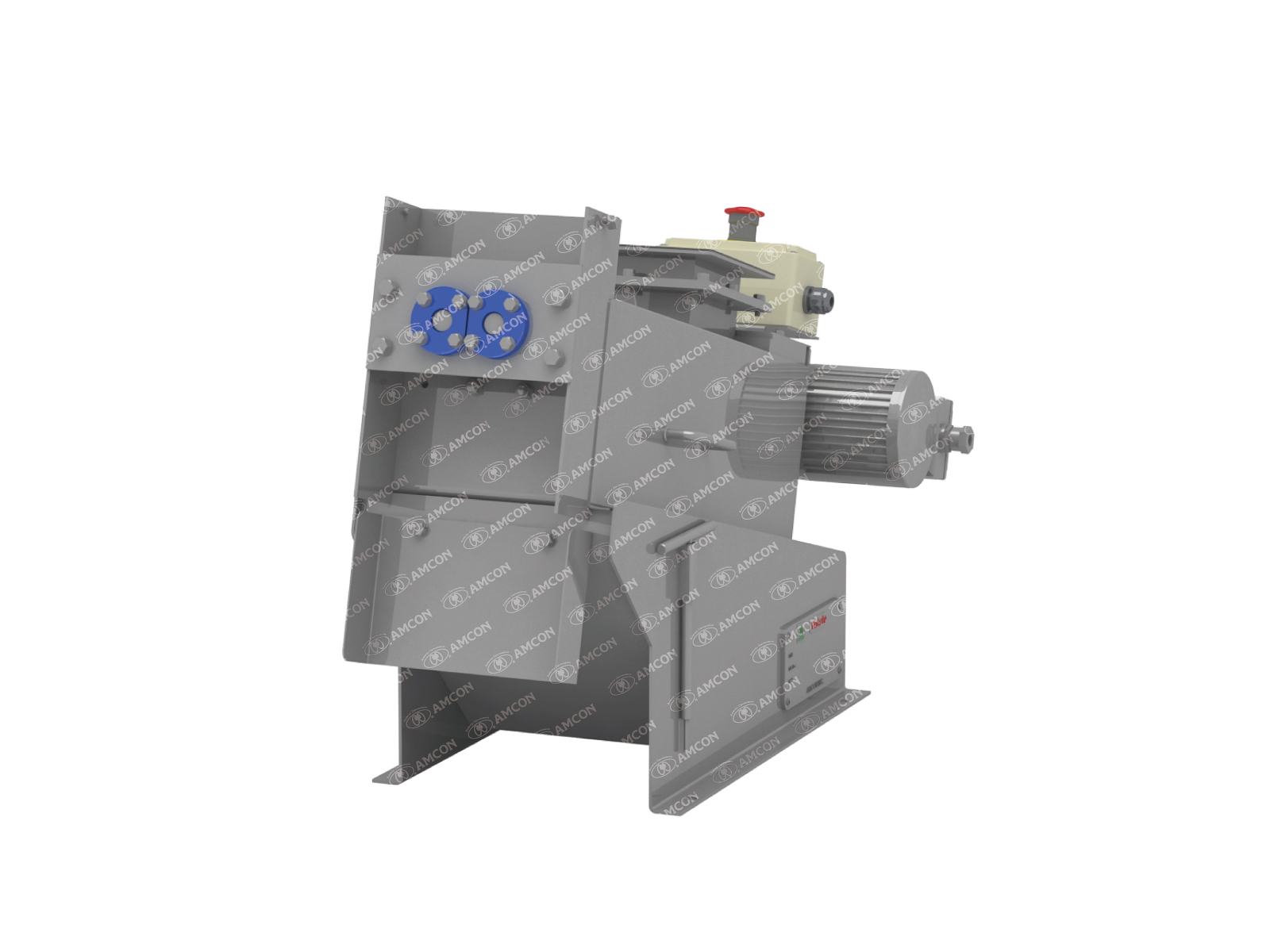

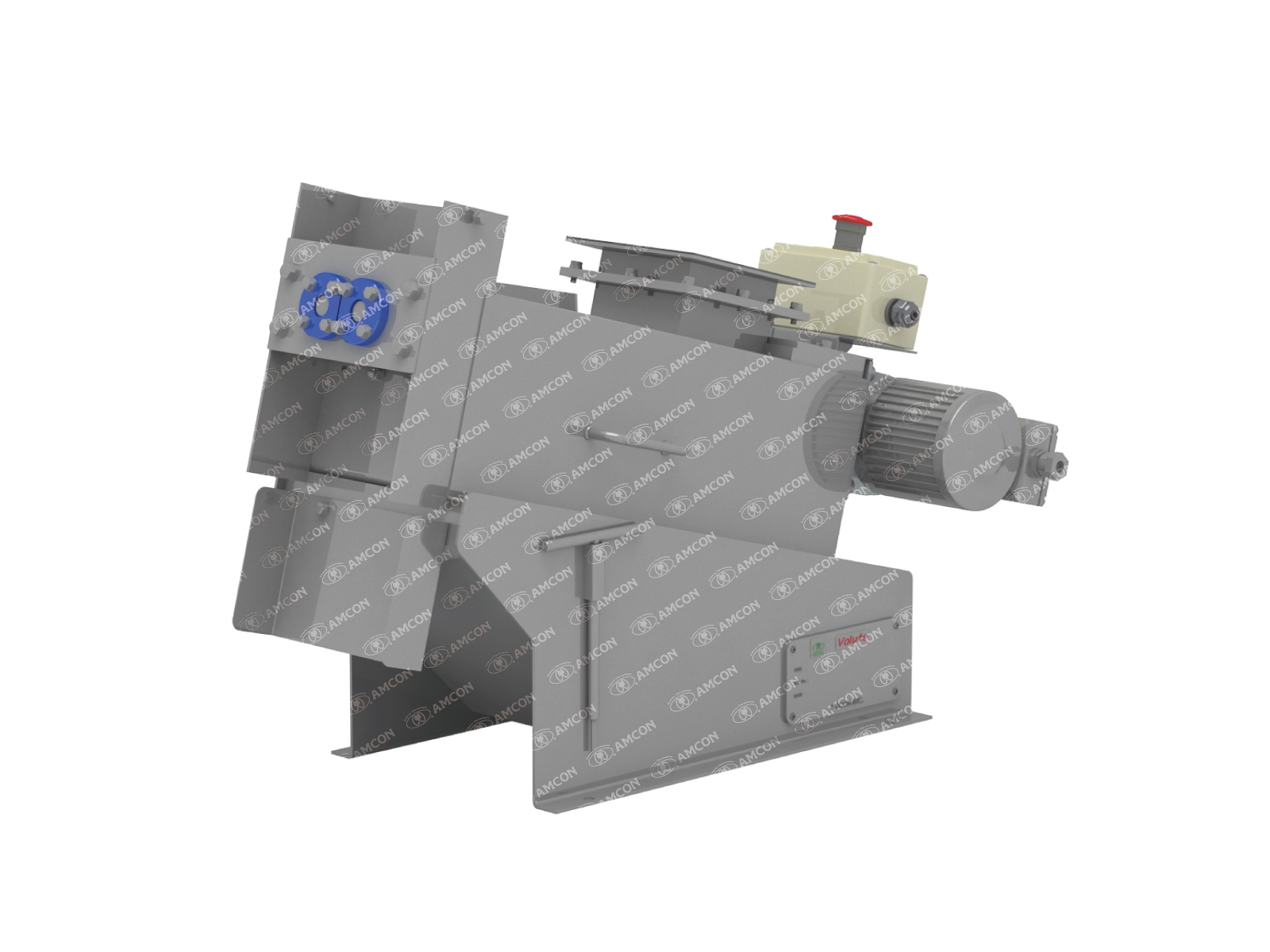

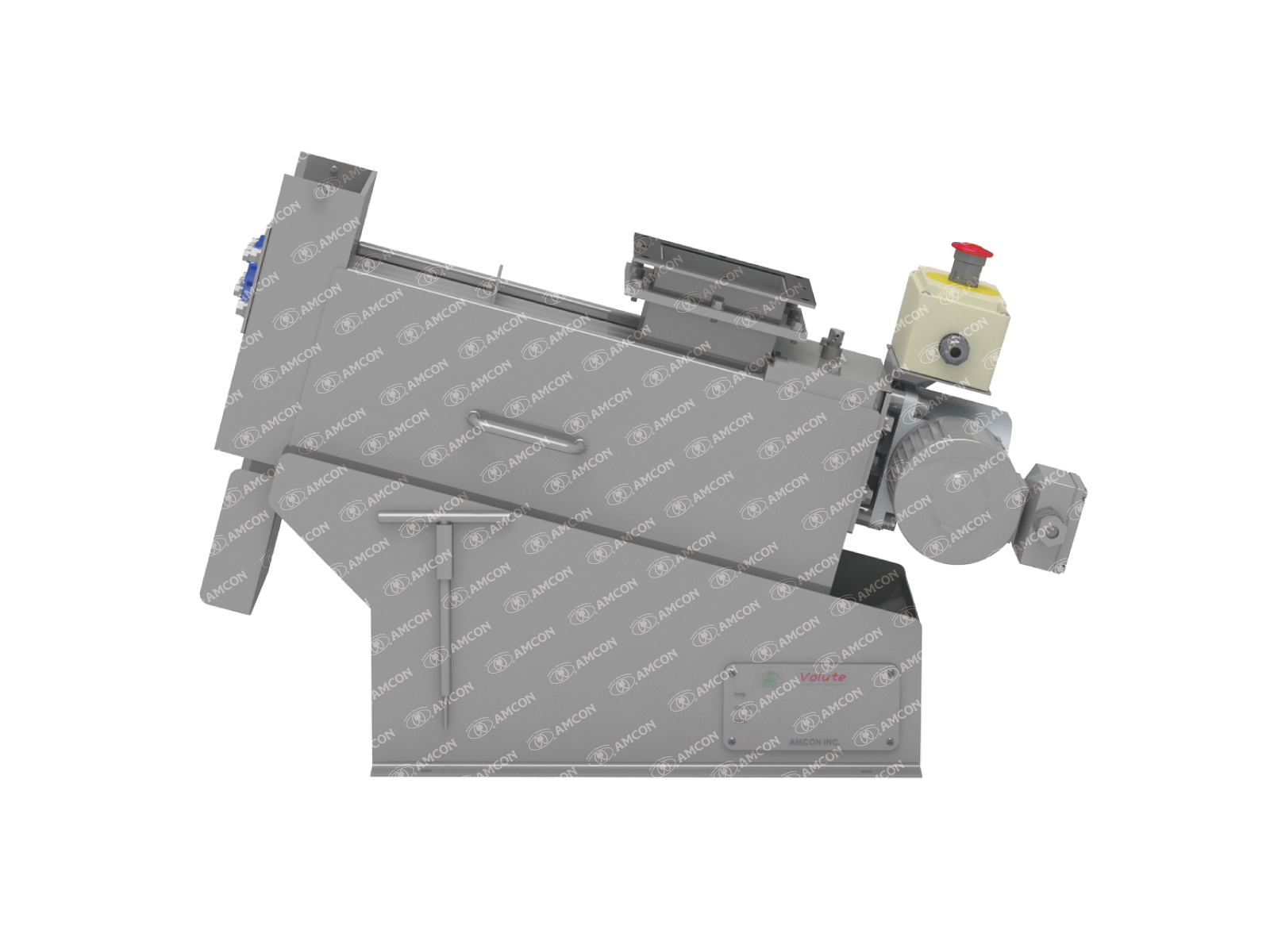

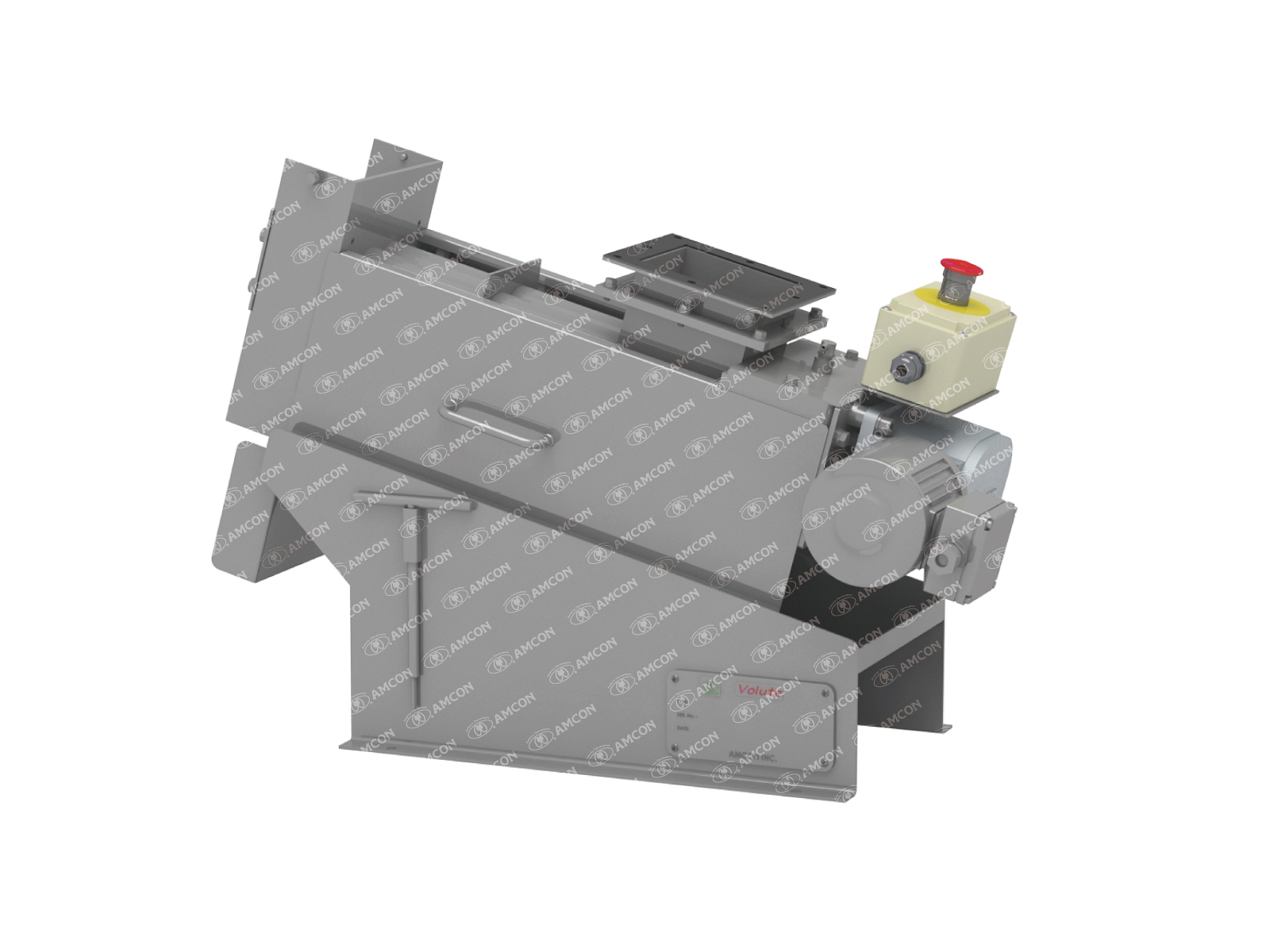

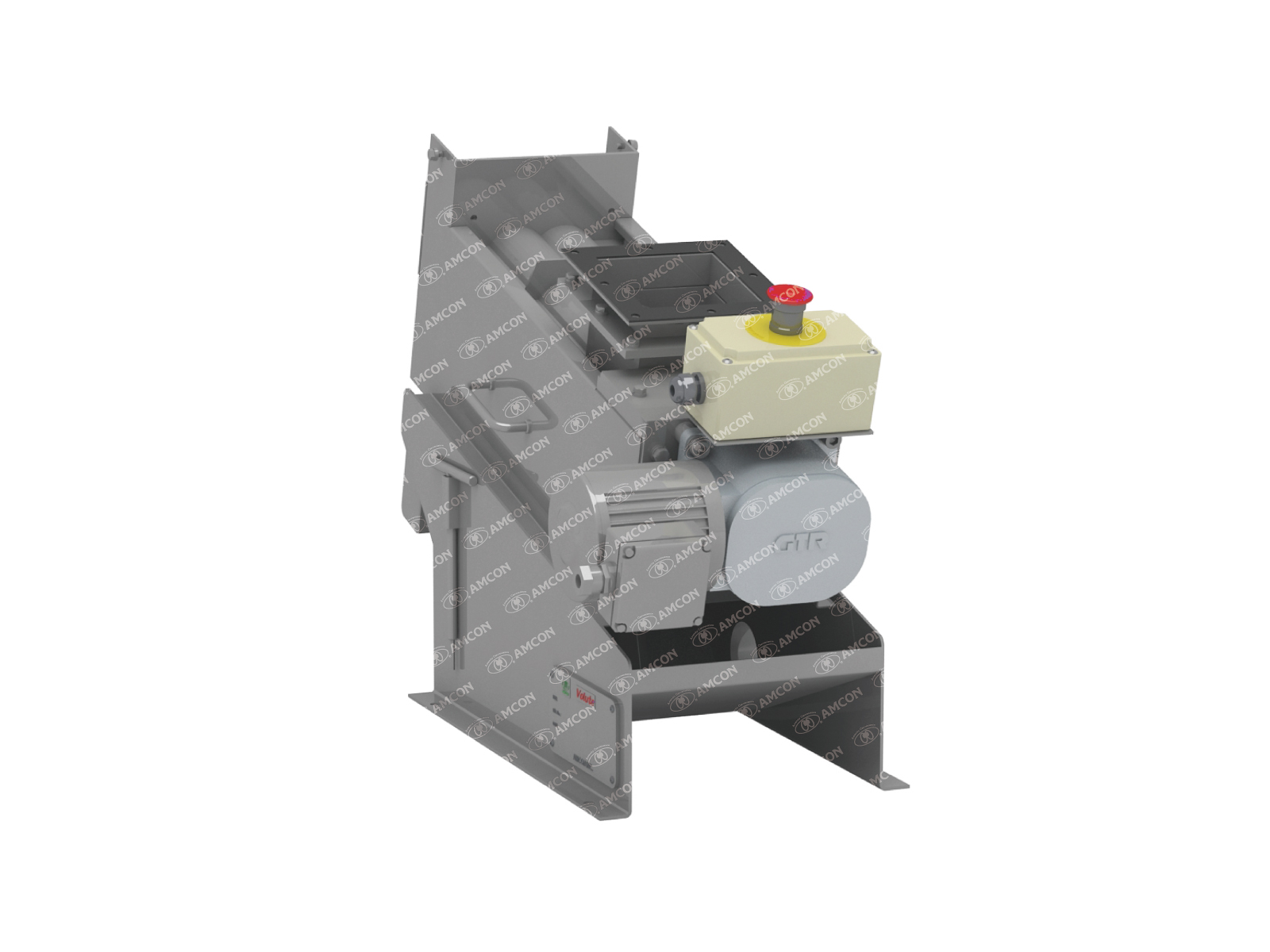

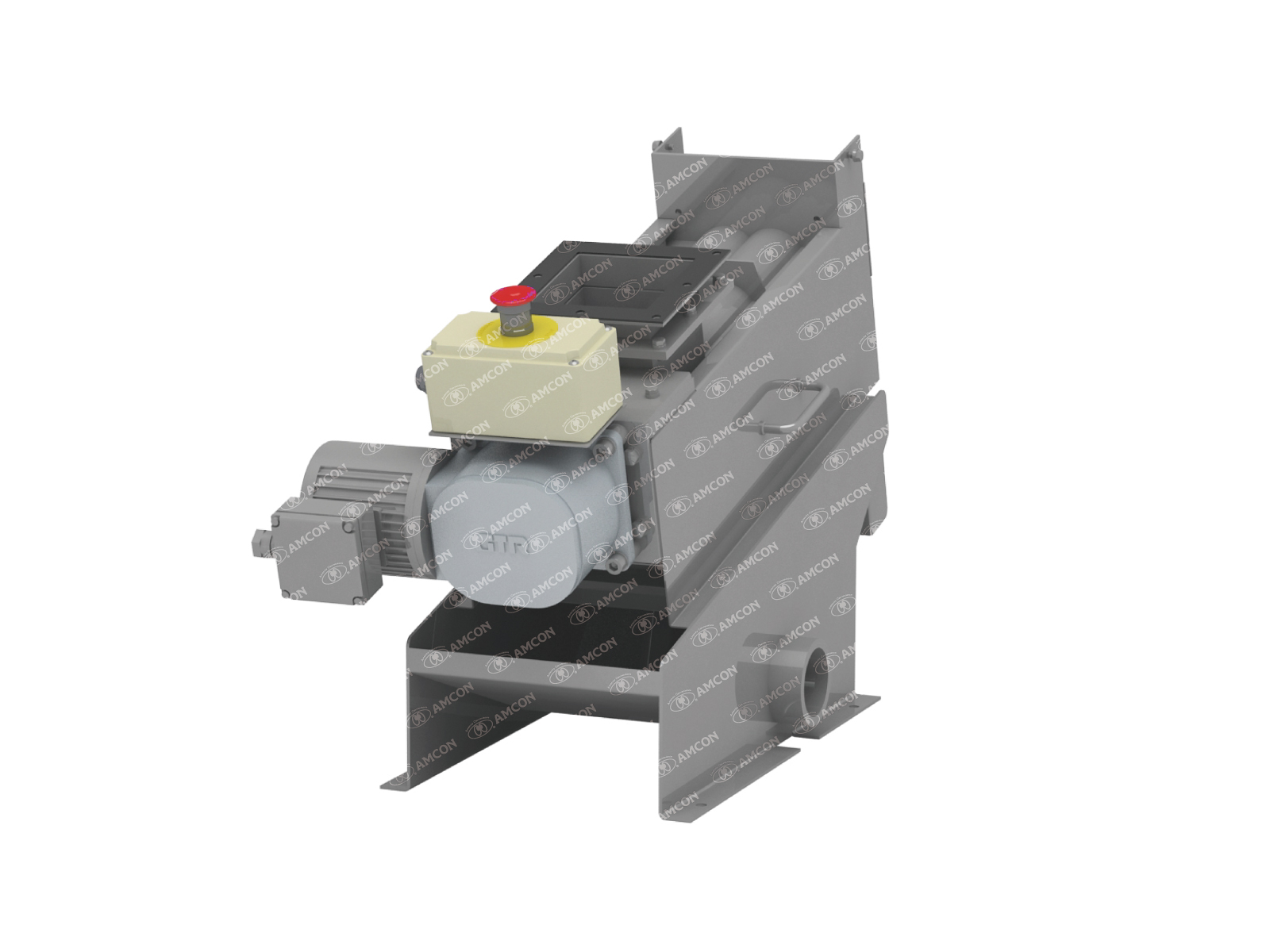

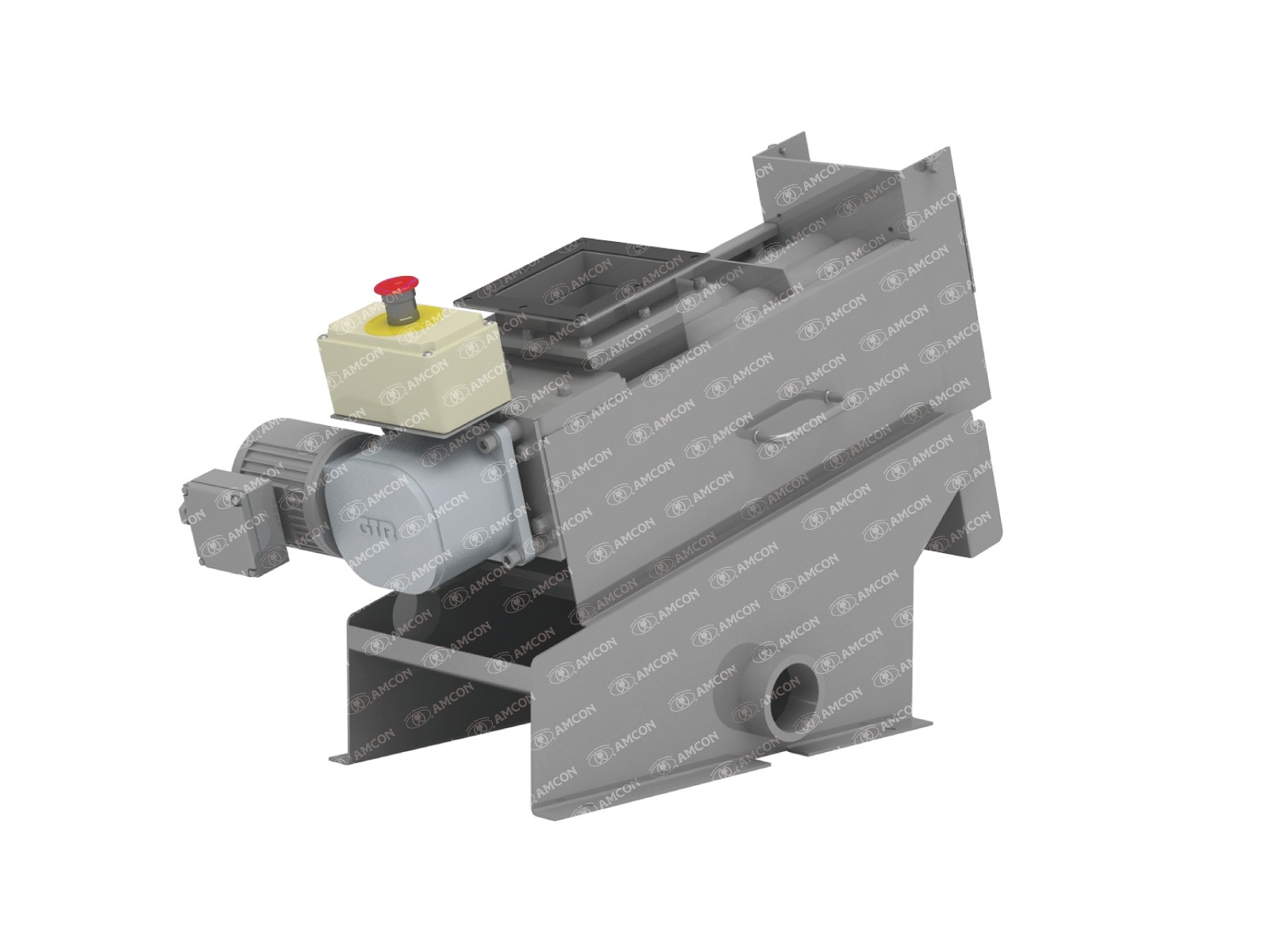

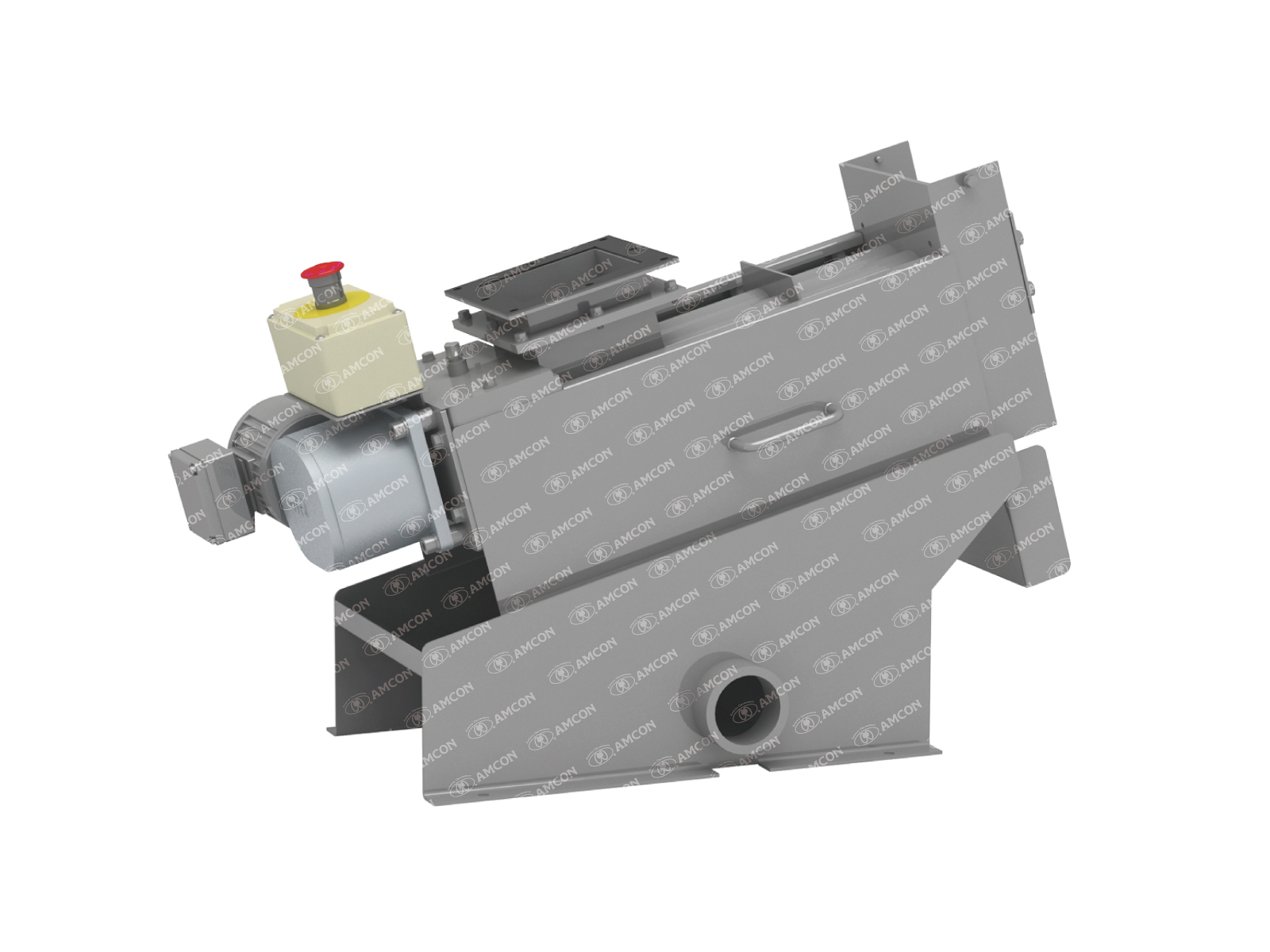

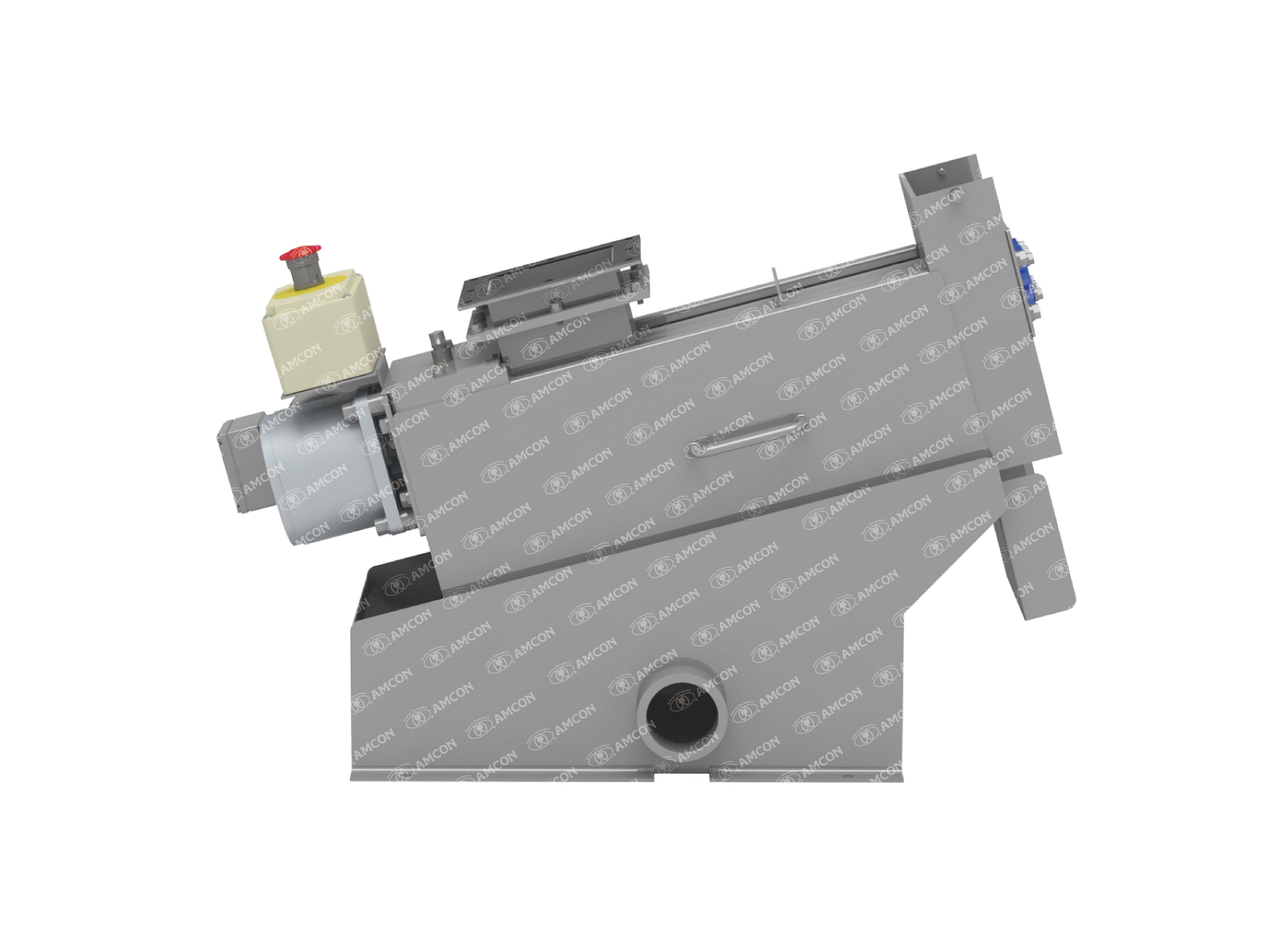

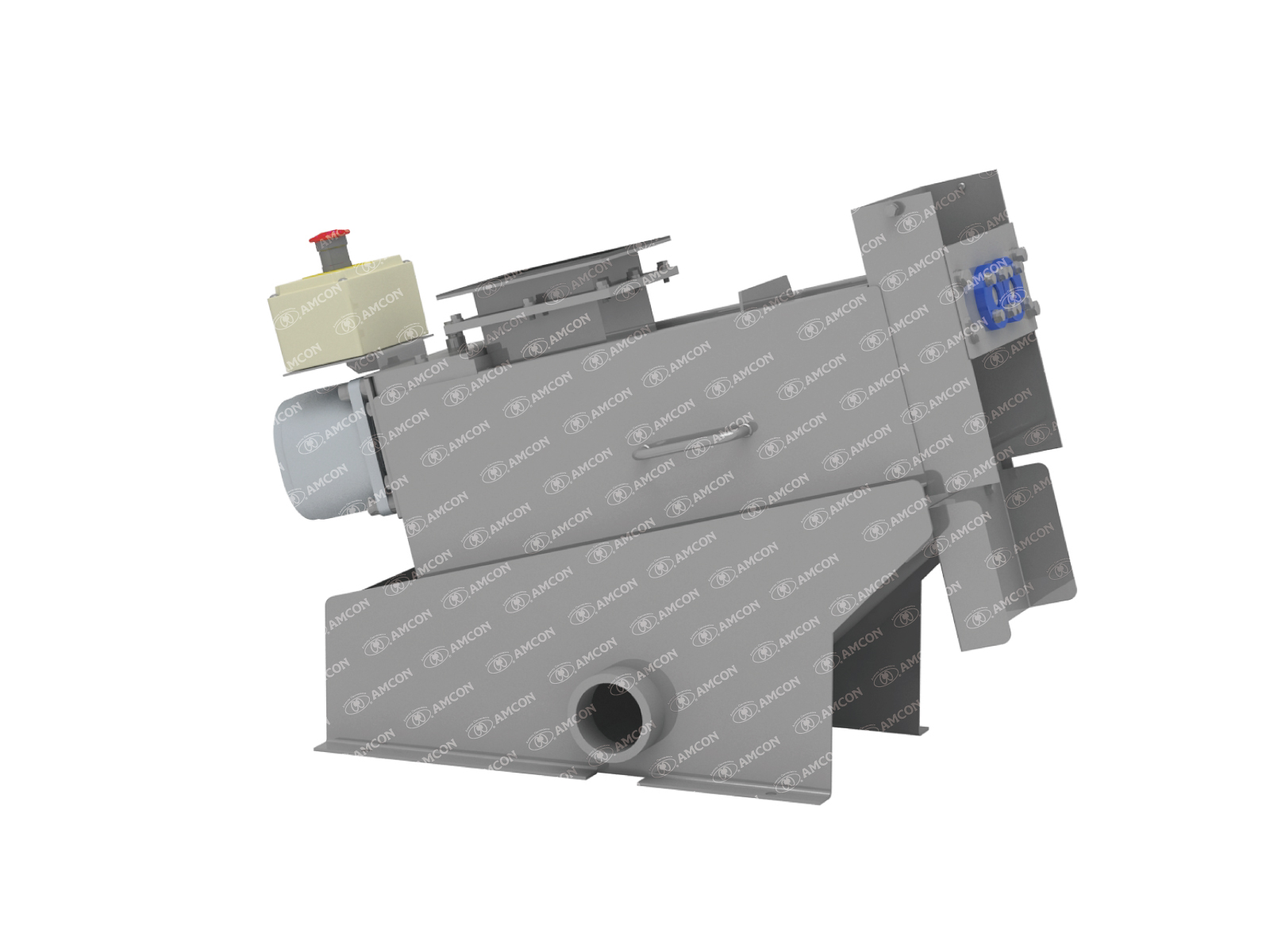

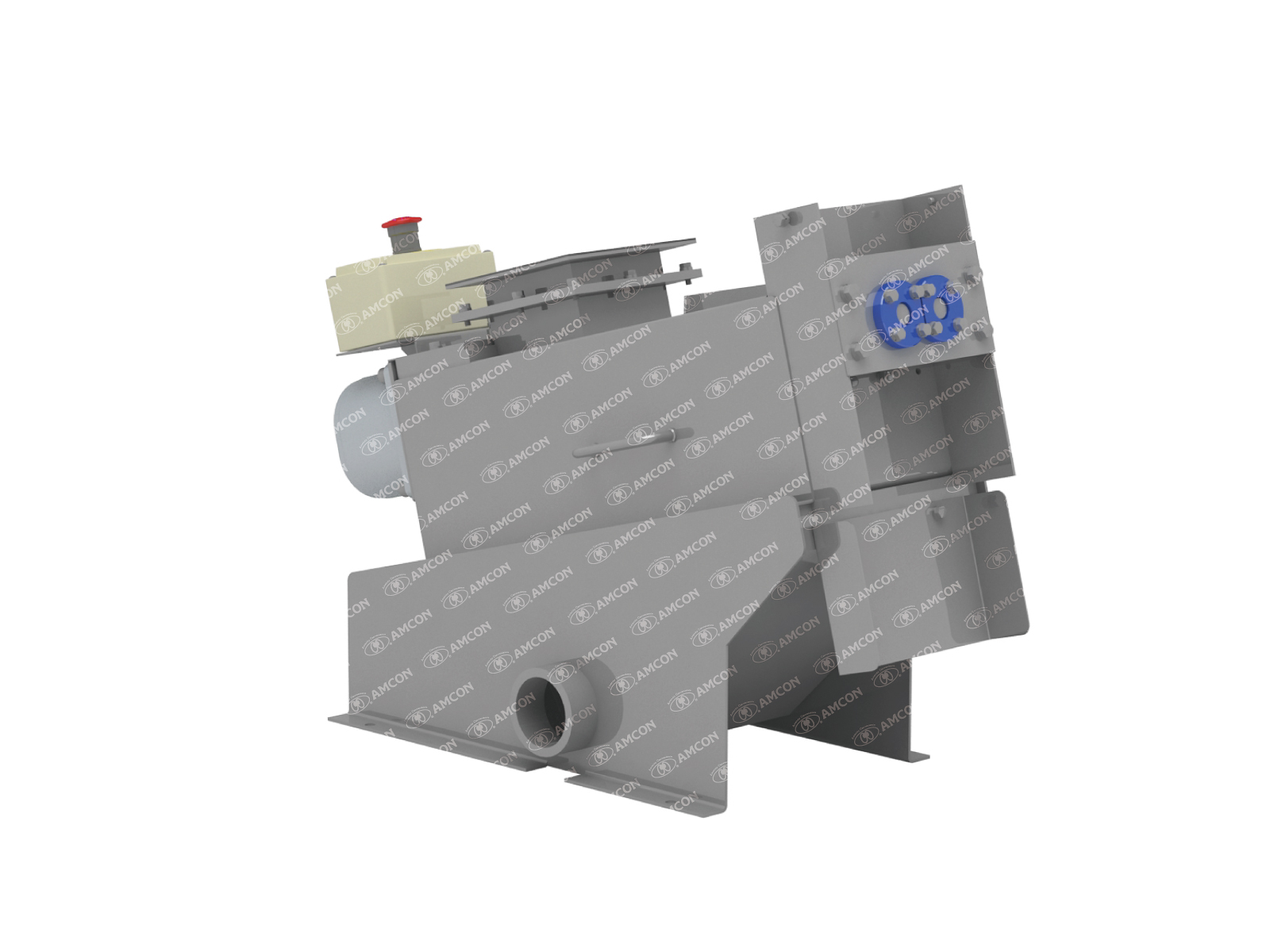

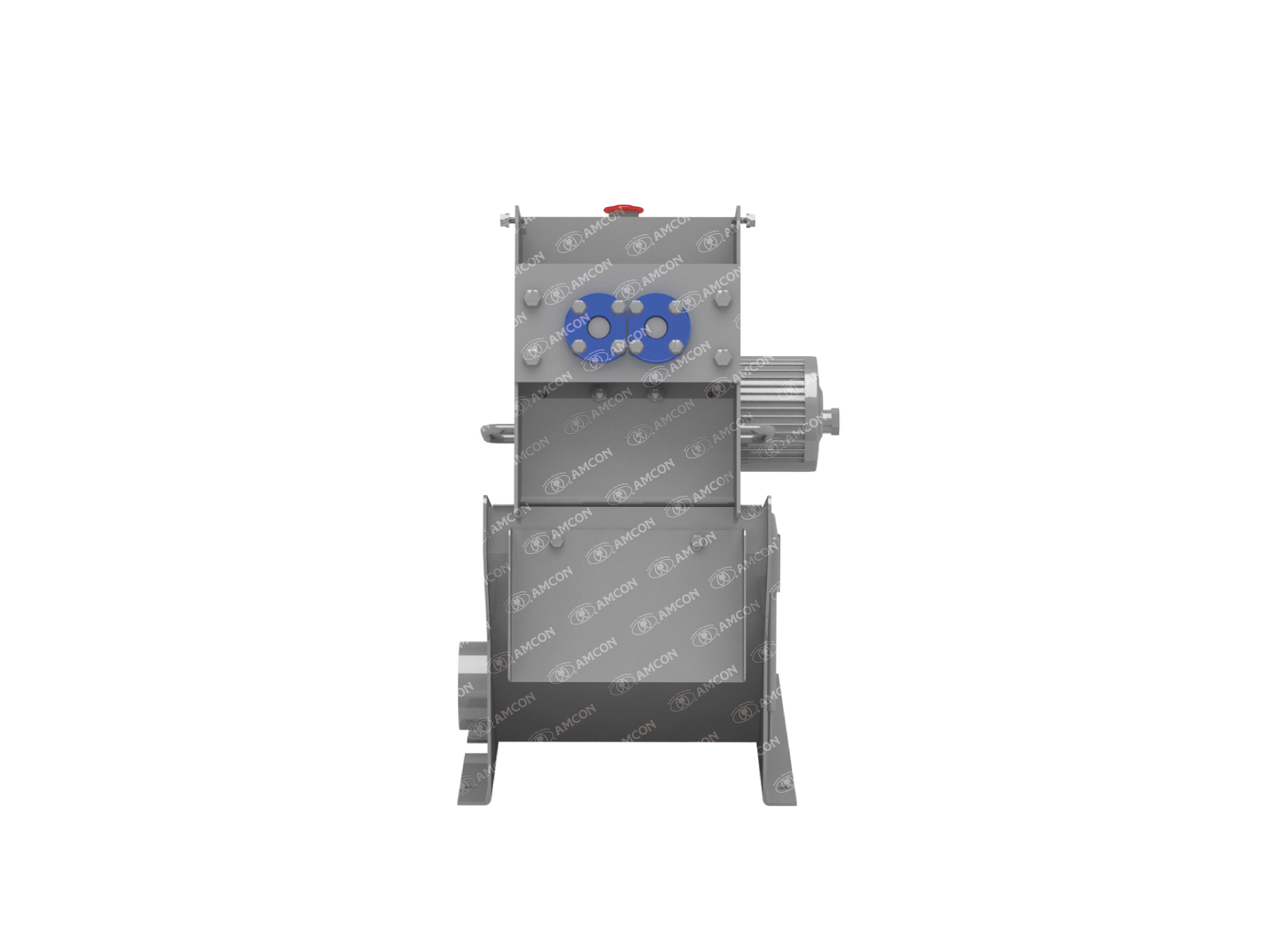

The TV-50F consists of a filter and two screws passing through the filter. The filter comprises two types of rings, fixed and moving rings. The screws convey and compact waste photoresist. The flights of the screws overlap each other. The rotating flights cut into the waste while the waste is flowing towards the outlet. This design helps achieve high dewatering efficiency and stable dewatering treatment.

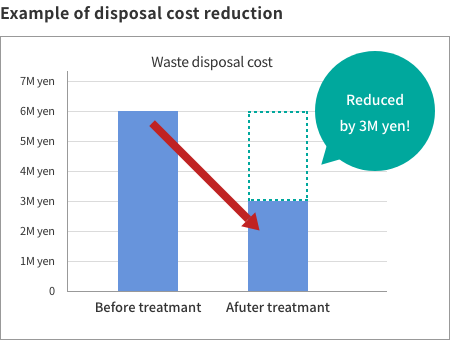

Reduce disposal cost

Waste disposal cost is reduced by dewatering waste dry film photoresist containing photoresist remover and reducing the amount of waste to 30% to 65%. Reduction in the amount of waste will also shorten the time required for transportation and disposal.

| Production capacity | 360,000㎡/year(30,000㎡/month) |

|---|---|

| Waste generation | 60t/year |

| Waste disposal cost | 100yen/kg or 20,000yen/drum |

| Waste redution by dewatering | 50% |

| Dewatering capacity | 30kg-WET/h max. |

*This cost estimate does not include transport, equipment maintenance, operation and running costs.

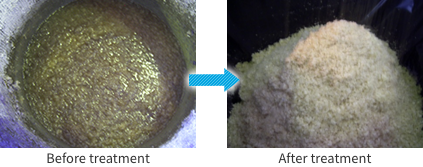

Improvement of work environment

Before dewatered, waste dry film photoresist is mixed with photoresist remover and the water content is very high. The waste is a strong alkali. It is hazardous and it must be handled carefully in transport and disposal not to spill it. The waste, after dewatered by the TV-50F, is like grated cheese and it won’t drip the remover solution, which leads to the improved working environment for transport and disposal.

EXAMPLE OF USE