Improving the working environment by dewatering waste dry film photoresist

Semiconductor package manufacturing plant in Japan

- Waste Dry Film Photoresist Dewatering Press

- Machine parts

- Industrial waste disposal cost reduction

- Improvement of work environment

- Pilot test/rental

- Semiconductor package manufacturing plant in Japan

Their problem

At this plant, waste dry film photoresist containing a lot of liquid was manually put into drums for disposal. Because dry film photoresist is highly alkaline, it is dangerous to carry and dispose of it. The company was looking for a way to improve the working environment by removing the liquid from the dry film photoresist for ease of handling.

AMCON’s solution

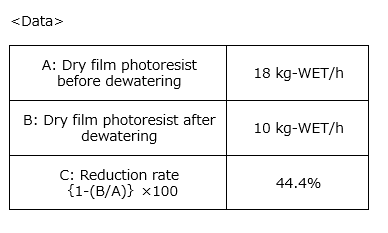

Pilot test with VOLUTE™ TV-50F dewatering press for waste dry film photoresist proved that it could dehydrate the waste to a grated cheese-like state with no liquid dripping. In addition to improving the work environment, which was the objective at the beginning, the dewatering process reduced the amount of the waste by approximately 44% and led to a reduction in disposal costs, which is why the company decided to install the system.