Eliminate needless procedures with VOLUTE DUO™ and cut down on maintenance costs!

Campo Azul (tequila distillery) in Mexico

- Sludge dewatering press

- Food Beverage

- Dewatering fibrous sludge

- Industrial waste disposal cost reduction

- Initial cost/outlays for construction reduction

- Operation management man-hour reduction

- Campo Azul (tequila distillery) in Mexico

Their problem

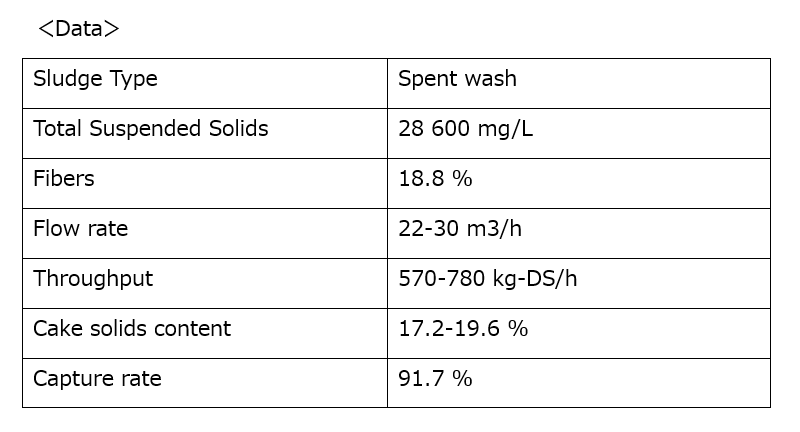

We would like to provide you with a success story of our revolutionary large scale dewatering machine “RVP-802 (aka = VOLUTE DUO™)” which is installed at a tequila distillery for wastewater treatment in Mexico (Campo Azul).

Our customer was using a simple sedimentation tank to draw the coagulated byproduct produced throughout the distilling process, and was not using a dewatering press. With increased production, our customer was having difficulties in treating the byproduct waste with a simple coagulation tank. This is where our product shines.

AMCON’s solution

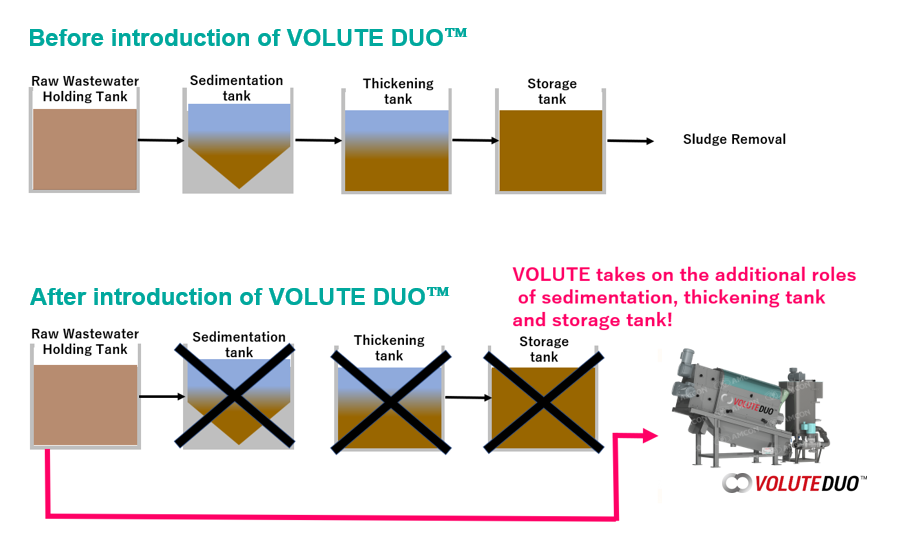

The most common process-flow of our VOLUTE™ is from raw water→wastewater treatment (generated sludge) → coagulation sedimentation layer → storage layer → dewatering machine. However, in this case, it was possible to treat the raw water directly through our VOLUTE DUO™ without having to go through the wastewater treatment flow. One of the reasons for this was that the raw water contained a large amount of fibrous material (18%) included in the manufacturing process. For the previous VOLUTE models, they had to be modified to treat such sludge, however, for our new model – VOLUTE DUO™, such modification have become unnecessary.

After the introduction of our VOLUTE DUO™, the volume of generated sludge was reduced and led to the following:

- A decrease in the amount of sludge drawn by a vacuum vehicle, which resulted in a significant reduction in cost.

- A reduction in manual labor as the task of transporting raw water to the coagulation sedimentation tank, previously done by workers, can now be handled solely by the dewatering machine.

Furthermore, we have received positive feedback from our customers that the flow rate of sludge and polymers, as well as the machine status, can be easily understood through the touch panel screen on the control panel.

We have previously communicated to all our customers that our VOLUTE DUO™ still has untold potential in its capabilities, and this time, we have glimpsed at yet another aspect of its latent abilities. There is no doubt that VOLUTE DUO™ still holds many unseen possibilities. If you are experiencing difficulties with sludge dewatering, please do not hesitate to reach out to us.