What are the ways to improve the efficiency of a sludge dryer? This article will attempt to explain the answers to this question. To maximize the efficiency of a sludge dryer, specific techniques will be necessary. By understanding the characteristics of different types of sludge dryers and the factors that influence their efficiency, you can reduce energy costs and shorten processing times.

Contents

What is a Sludge Dryer?

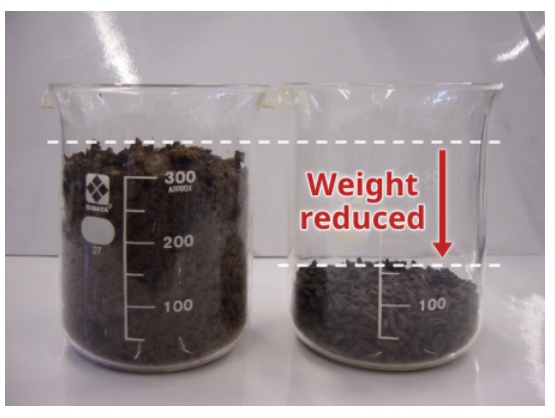

A sludge dryer is a device that reduces the volume of sludge by drying it. The sludge itself can be generated during wastewater treatment and effluent treatment processes. By reducing the volume of sludge, it is possible to cut down on transportation and disposal costs. Additionally, dried sludge can also be reused as a recyclable resource.

As you can see, sludge dryers play an important role in both environmental protection and economic efficiency.

Purpose of a Sludge Dryer

- Reduction of sludge volume

- Reduction of transportation and disposal costs

- Reuse as a recyclable resource

- Improvement of sanitary management

- Reduction of environmental impact

Basic Mechanical Structure of a Sludge Dryer

Sludge dryers generally have the following mechanical structure.

※Please note that the structure may vary depending on the type of sludge dryer.

| Component | Description |

|---|---|

| Sludge Inlet | The Section where the sludge is fed. The sludge is then sent into the machine for drying purposes. |

| Drying Chamber | The section that dries the sludge. Heating apparatus and rotating mechanisms are installed here to heat and evaporate the moisture. |

| Heating System | There are a few methods in heating the sludge. The first one is Direct Heating (burning gas or oil to generate hot air) and second is Indirect Heating (transmitting heat using heaters or steam). |

| Agitation/Mixing Apparatus | The section that stirs the sludge to ensure even drying. Parts such as screws, rotors, and rotating drums are installed in this section. |

| Discharge Section | The section where the dried sludge is discharged. It often consists of filters or chutes. |

The Advantages of Sludge Dryers

The advantages of sludge dryers are as follows:

- Reduced moisture content in sludge makes handling of sludge cakes easier.

- Dried sludge can be reused, contributing to efficient resource utilization.

Types of Sludge Dryers

Here are the different types of sludge dryers. Each dryer has its advantages and suitable applications, making the selection of the appropriate model essential for efficient sludge drying.

Rotary Drum Dryer

This method dries sludge within a rotating drum using hot air to evaporate the moisture. It is commonly used when the sludge moisture content is moderate or when uniform drying is required.

The SP series of sludge dryers by AMCON INC. achieves high thermal efficiency by directly exposing the dewatered cake to the heat source. Its unique double-drum structure provides sufficient drying areas while maintaining a compact design.

For more details on our SP series, click here →

For inquiries, contact us here →

Belt Sludge Dryer

This method spreads the sludge on a long belt conveyor and dries it by blowing hot air onto it. It allows for continuous operations which is suitable for when the sludge moisture content is high or when large quantities need to be processed. This type of dryer is widely used for industrial applications.

Fluidized Bed Dryer

This method uses hot air or steam to levitate the sludge into a fluidized state for drying. It is highly efficient in heat exchange and can dry sludge in a relatively short time.

Paddle Dryer

A paddle dryer has paddles (mixing blades) inside, which operates by stirring the sludge while drying it. It enables uniform drying and is suitable for handling highly viscous sludge.

Disk Dryer

A disk dryer uses a structure with stacked circular disks. The sludge is supplied between the disks and dried while the disks rotate and heat up. It allows for efficient heat exchange within a compact space.

Vacuum Dryer

A vacuum dryer places the sludge inside a vacuum chamber and dries it at a low temperature in a vacuum state, minimizing changes in sludge composition.

Factors Influencing Efficiency

Heat Source Selection

Choosing the right heat source is crucial in improving the efficiency of sludge dryers. There are various heat sources, each with their advantages and disadvantages.

| Heat Source | Advantages | Applications |

|---|---|---|

| Gas (Natural Gas, Propane Gas, etc.) | Instant heating possible | When the throughput volume is large |

| Efficient combustion and easy to adjust temperature | When continuous operations are required | |

| Oil (Heavy Oil, Light Oil, etc.) | Relatively low fuel costs | Regions where gas supply is difficult |

| Reducing fuel costs | ||

| Electricity | Easy temperature control, clean energy | Small-scale sludge drying |

| Compact design | ||

| Steam | Stable heat supply, affordable | Facilities with existing steam infrastructure |

| Easy integration with existing factory equipment | When low-temperature drying is required | |

| Using Waste Heat (i.e. exhaust heat at factories, process heat, etc.) | Reduces energy costs | Factories/facilities where waste heat can be obtained from other processes |

| eco-friendly | ||

| Infrared heating | Localized heating is possible | For small-scale sludge drying |

| High drying efficiency |

Optimizing Energy Consumption

- Optimizing energy consumption is vital for improving the efficiency of sludge dryers. Besides selecting an appropriate heat source, the following methods are important:

- Improving insulation to minimize heat loss.

- Automating processes for efficient operation.

- Introducing heat recovery systems to reuse released heat.

Introducing Technology for Efficiency

Modern technologies are essential for improving sludge dryer efficiency. Notable technologies include:

- Heat pump technology.

- Energy-saving heat sources.

- Automated control systems.

These technologies listed above reduce energy consumption, lower operating costs, and ensure stable processing.

Conclusion

In this article, we explained how to maximize the efficiency of sludge dryers.

To maximize the efficiency of sludge dryers, a multifaceted approach is required, including selecting the right type of machine, optimizing the heat source, and optimizing energy consumption.

Why not use this article as a reference to improve the efficiency of your sludge dryer?