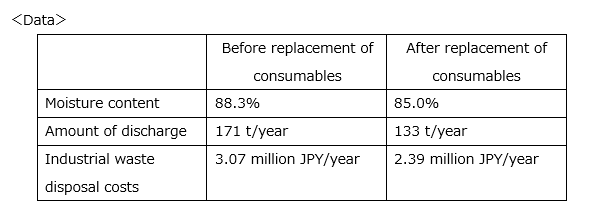

Moisture content decreased by 3.3 percentage point after replacing consumables. The cost of sludge disposal as industrial waste was reduced by 680,000 JPY/year.

Confectionary and ready meal production plant in Japan

- Sludge dewatering press

- Food Beverage

- Industrial waste disposal cost reduction

- Confectionary and ready meal production plant in Japan

Their problem

In this plant where confectionery and ready meals are produced, a VOLUTE™ EC series sludge dewatering press has been used. Our service engineer visited the plant for inspecting the machine and found some wear in the filtration section.

AMCON’s solution

By replacing consumables at the right time, you can use the dewatering press for an extended period while maintaining high dewatering performance. In addition, replacing worn parts may allow dewatering with the original performance and lower the moisture content, thereby reducing the cost of sludge disposal as industrial waste.

This plant also decided to replace consumables, and as a result, the moisture content was reduced from 88.3% to 85%, and the cost of sludge disposal as industrial waste was reduced from 3.07 million JPY to 2.39 million JPY/year. The timing of replacing consumable parts can be determined by checking two points: “operation time”, and “condition of the filtration unit (cylinder)”. Please contact us for details.