“What kind of sludge thickeners are there?” “Which sludge thickener would be best for our factory?” If you have these kinds of questions, this guide will introduce the features of different types of sludge thickeners and how to choose the right one.

Contents

What exactly is a Sludge Thickener?

In wastewater treatment plants and various industrial wastewater treatment processes, sludge with solids concentration of about 0.4% to 2% is usually thickened to around 4%. This process is called sludge thickening.

thickener is to act as a preliminary step for the sludge dewatering process or digestion process in wastewater treatment plants. In such treatment systems of hotels, large commercial buildings, or gray water recycling facilities, it is often introduced to reduce the volume of sludge that ultimately needs to be vacuum-extracted and disposed of. For example, by thickening sludge with a 1% solids concentration to 4%, the volume of sludge to be discharged can be reduced to a quarter of the original volume, contributing to cost reductions and increased efficiency in sludge treatment.

Benefits of having a Sludge Thickener

Introducing a sludge thickener offers various advantages. The main benefits are as follows:

- The reduction of sludge treatment costs

- Minimization of the workload within sludge treatment plants

- Mitigation of negative environmental effects

- Improves treatment efficiency

Reduction in Sludge Treatment Costs

By reducing the volume of sludge with a sludge thickener, the subsequent transportation, treatment, and disposal costs can be significantly reduced. In many cases, the savings from reduced treatment costs surpass the initial investment in the thickener, leading to substantial long-term cost benefits. In urban commercial facilities, where sludge treatment systems are often located underground, it can be difficult to extract the dewatered sludge cakes. Therefore, converting the sludge into thickened, vacuum-extractable sludge can reduce the total volume of sludge to be removed.

Reduced Load on Sludge Treatment Facilities

By decreasing the volume of sludge, the load on the subsequent sludge treatment systems, such as sludge dewatering machines and incinerators, is reduced. This also extends the lifespan of the equipment, contributing to lower maintenance and management costs.

Mitigation of Negative Environmental Impacts

Since the amount of sludge generated is reduced, the environmental impact associated with treatment (such as CO2 emissions) is also diminished. Additionally, thickened sludge opens up more possibilities for being effectively utilized as a resource or energy source.

Improved Treatment Efficiency

As sludge concentration increases, the efficiency of the subsequent sludge treatment processes will improve. For example, by enhancing the performance of sludge dewatering machines, treatment durations can be shortened, and the amount of chemicals used can be reduced.

How to Choose a Sludge Thickener

When selecting a sludge thickener, it is essential to consider the following factors comprehensively:

- Throughput/Treatment Capacity

- Implementation and Running Costs

- Implementation Space

Treatment Capacity

Make sure to bear in mind the amount of sludge to be processed per day (m³/day), the concentration of the sludge, and the required concentration of the sludge after thickening. If the capacity of the device is insufficient, the sludge treatment may fall behind, potentially affecting the entire process.

Installation Cost

The installation cost of a sludge thickener can vary significantly depending on the model, treatment capacity, and its installation work required. It is important to choose the most suitable model within your budget.

Running Costs

Operating a sludge thickener incurs various costs, such as electricity, chemicals, and maintenance. It is crucial to consider these costs through a long-term perspective.

Installation Space

Ensure that you have enough space to install the sludge thickener. The required space differs depending on the model, so it is important to check the available space beforehand.

Types and Features of Sludge Thickeners

Here, we will introduce the types and features of sludge thickeners. Sludge thickening methods can be categorized into two types: (1) gravity thickening and (2) mechanical thickening.

1. Gravity Thickening

This is the simplest thickening method, which uses the difference in specific gravity to thicken the sludge. Sludge is inserted into a thickening tank, where the thickened sludge settles due to gravity and is drawn from the bottom. This method is sensitive to sludge characteristics, and if the retention time becomes too long, the sludge may decay, leading to the generation of odor.

2. Mechanical Thickening

I. Belt-Type Thickener

A belt-type thickener feeds flocculated sludge onto a moving belt, and thickening is achieved through gravity filtration. Its thickening principle and the machine’s structure are rather simple, making operation and adjustments easy. However, continuous belt cleaning will be required during operation, resulting in the usage of large amounts of cleaning water.

II. Centrifugal Thickener

A centrifugal thickener uses centrifugal force generated by high-speed rotation to thicken the sludge. A screw conveyor inside the rotating drum transports and discharges the settled thickened sludge. Since the machine is sealed, odor generation is minimal, but the due to the high-speed rotation, it consumes a large amount of power.

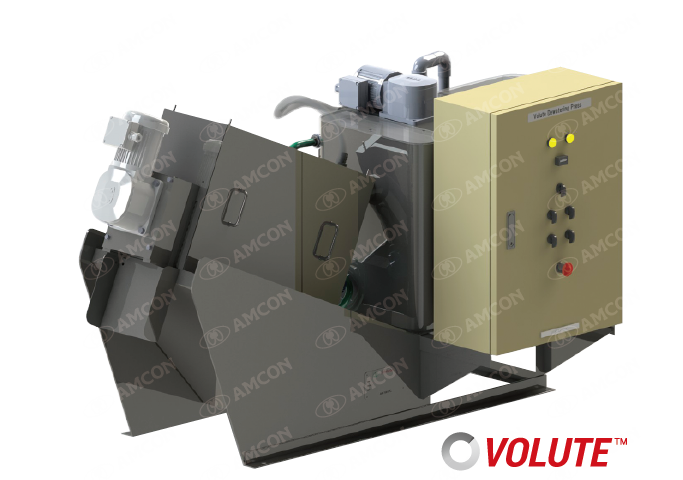

III. Multi-Disc Screw Press Thickener

This screw press thickener uses compression, driven by the rotation of a screw, to thicken the sludge. Its compact design requires little installation space, and the extremely slow screw rotation results in very low power consumption.

For more information on our VOLUTE™ sludge thickener, click here →

Mechanical thickeners can produce a stable output of thickened sludge, which is difficult to achieve with gravity thickening.

Conclusion

In this article, we provided a comparison between several types of sludge thickeners, highlighting the different features of each type. We urge you to thoroughly consider this information when selecting a sludge thickener that suits your needs.